A direct-drive roller conveyor is a transport system designed to provide continuous movement of loads of various weights and sizes over a specified distance. Its key feature is the presence of a gear motor that drives the entire structure..

The powered roller conveyor (roller table) is designed for transporting unit loads with a flat bottom, such as boxes, pallets, wooden blanks, trays with products, and similar items. It is used to move goods within a workshop or between workshops and warehouses. These conveyors are widely utilized across various industries and help reduce labor costs associated with storage and material handling operations.

A powered roller conveyor is equipment that allows loads to be moved either horizontally or at an incline to a certain height. Unlike belt conveyors, roller conveyors can transport significantly heavier loads—up to 1500 kg/m³—making them suitable for demanding industrial applications.

Features and Design of the Straight Powered Roller Conveyor

Visually, the powered roller conveyor features a frame structure with a specific number of rollers fixed to it. The conveyor rollers are cylindrical in shape and are mounted on stationary shafts, rotating with the help of ball bearings. The rollers are driven by a motor-reducer, which is connected to them via a chain or belt transmission system.

The spacing between rollers can vary depending on the application; however, it is recommended that the distance does not exceed 1/3 of the length of the transported item to ensure stable and smooth movement.

Thanks to its ability to transport loads not only horizontally but also at a slight upward angle (up to 7° for heavy loads and up to 12° for lighter ones), the powered roller conveyor enables the automation of cargo movement throughout a warehouse or production facility. It also allows for the design of routes with virtually any geometry, making it a versatile solution for streamlining internal logistics.

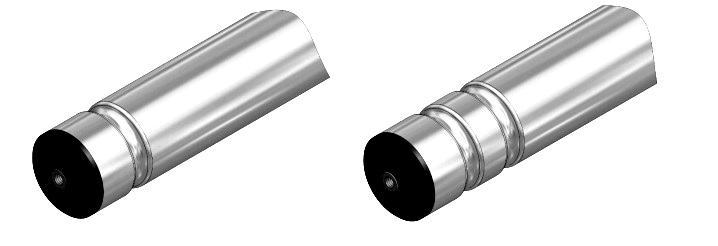

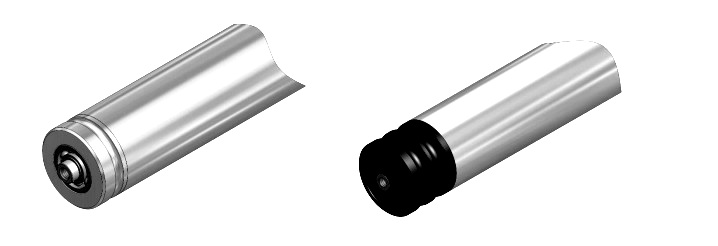

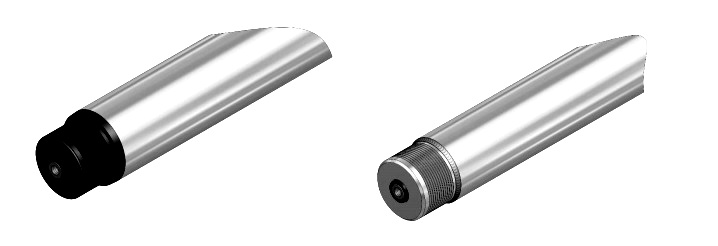

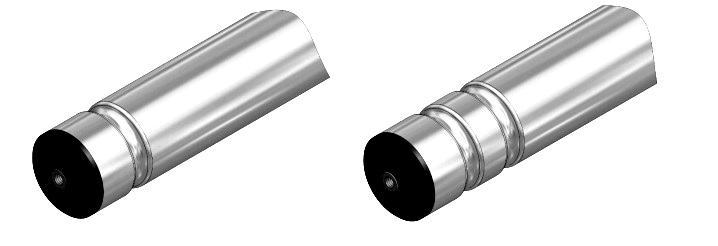

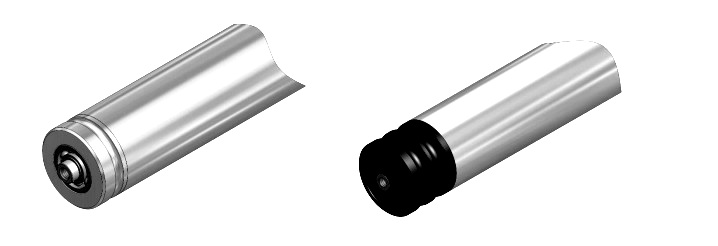

Driven Rollers

Driven rollers consist of a housing, spindle, bearing, and drive element. The roller shaft is connected to the power transmission component, which may be a sprocket or a pulley. Driven rollers receive torque through a shaft with a keyway input, for example, from a gear motor mounted directly to the sides of the conveyor. In this way, further power transmission from one roller to another within the conveyor is possible using a chain or belt.

A roller conveyor can be powered in various ways. When selecting a drive system, it is important to consider the following:

- weight of the load;

- transportation speed;

- drive concept (non-rigid drive / rigid drive);

- length of the conveyor;

- environmental conditions;

- type of drive element.

Available types of roller conveyor drives:

- Flat belt drive. Conveyor rollers are driven by a flat belt located underneath the rollers. This drive concept is compatible with all roller conveyor series equipped with bearings.

- Round belt drive. Motion transmission using a round belt is carried out either from roller to roller or via a vertical axis positioned beneath the roller.

- Poly-V belt drive. Conveyor rollers are driven by ribbed belts.

- Timing belt drive. Conveyor rollers are equipped with a toothed element, featuring trapezoidal or semi-circular shaped teeth, and are driven by a timing belt.

- Chain drive. Conveyor rollers are equipped with drive sprockets and are powered by a chain, depending on the drive concept. Types of chain drive include:

- Tangential drive – multiple conveyor rollers equipped with drive sprockets are powered by a single continuous drive chain that runs tangentially alongside them. Only one tooth of the drive sprocket engages with the chain. The chain movement is guided by a chain guide and pressure rollers. If the tangential chain runs over the top of the conveyor rollers, the end rollers are in standard engagement.

- Loop (or ring) drive – conveyor rollers equipped with two drive sprockets are driven by a chain transmission in a paired roller-to-roller configuration. The chain transmits motion from one roller to the next, creating a looped drive system.

How to select the required drive rollers for a conveyor used for power transmission?

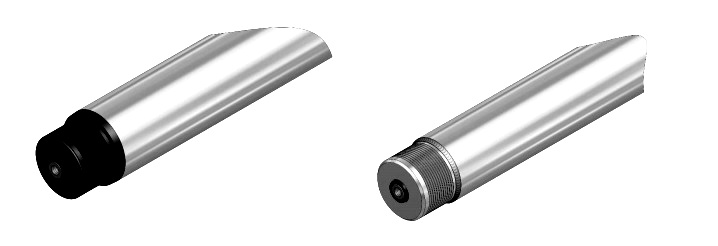

Grooved rollers provide power transmission using belts manufactured to a standard with two grooves spaced 30 mm apart for roller-to-roller power transmission, or a single groove for transmitting power from a shaft positioned perpendicular to the rollers. In the latter case, it is recommended to use special rings on the shaft to increase the belt's turning diameter, maintain its perpendicular position relative to the rollers, and ensure sufficient friction — all these elements significantly extend the lifespan of the belts.

In the case of stainless steel rollers, to prevent deformation of the tube in the grooves — especially in rollers with a diameter of no more than 50 mm — polyamide-headed rollers are used for power transmission with belts (suitable for use in the food industry).

Rollers with heads for power transmission using poly-V belts offer significantly higher efficiency compared to round belts. This type of transmission allows energy to be transferred from one motor roller to up to five rollers when using poly-V belts, making them particularly attractive for conveyor system applications.

Rollers with sprockets. Another method of power transmission is the use of a roller chain, which enables the movement of heavy loads. These rollers are available with single or double sprockets, providing power transmission using a standard roller chain.

Advantages of the drive roller conveyor from BK “VIMALSPETSBUD”:

- significantly reduce the labor intensity of the entire cargo movement process due to the presence of an electric motor;

- high performance. Increase processing productivity and the speed of loading and unloading operations;

- space-saving design. Allow for efficient use of production and warehouse areas due to their compact size;

- robust design. Characterized by structural reliability, long service life, and ease of operation;

- customized product design. Available in any configuration according to the customer's request. Conveyor length and load capacity can also be selected.

We are located in Chernihiv and manufacture straight driven roller conveyors of any size to order, based on customer requirements, in the shortest possible time and at attractive prices. You can purchase straight driven roller conveyors produced by VIMALSPETSBUD by submitting an online application or contacting us by phone. (Go to contacts)