We present to you the new product from BK "VIMALSPETSBUD" — the drum land separator, DESOILER screen.

The DESOILER land separator is a high-tech, economical, and self-cleaning piece of equipment designed to solve your root crop cleaning challenges, providing highly efficient separation of soil, sand, and debris from the overall flow.

Design and operating principle of the DESOILER land separator and screen from BK "VIMALSPETSBUD"

The desoiler consists of a metal frame with a screening drum mounted on it, driven by a motor-reducer via a belt drive, designed for cleaning root crops (potatoes, beets, etc.). The design allows for effective cleaning of root crops without causing damage.

The screening drum is equipped with a cleaning brush attached to the frame and driven by the motor-reducer. This ensures the desoiler operates at maximum efficiency, even when processing highly contaminated raw materials.

The movement of the raw material is achieved through the inclination and rotation of the drum. The root crops fed into the drum gradually move downward and are discharged onto a conveyor further along the processing line. Soil falls through the gaps in the screening drum and drops down below. Effective preliminary dry cleaning facilitates easier subsequent processing and reduces the impact of abrasive particles on the equipment. In turn, this leads to lower energy consumption costs.

Dry cleaning allows the removal of up to 85% of impurities (soil, sand, sprouts, foliage, etc.).

DESOILER is our own development, successfully performing its functions at processing enterprises in Ukraine, and has a number of advantages compared to other manufacturers, such as:

- Simple design (minimum moving parts that are very easy to maintain, durable rod drum);

- Removes up to 85% of impurities thanks to innovative technical solutions;

- High productivity with excellent cleaning efficiency;

- Easy maintenance due to an effective self-cleaning system;

- Simple process for full visual inspection and control.

DESOILER is the result of our 28 years of experience, embodied in a simple yet highly effective device designed for our working realities with European quality and a reasonable price.

Desoilers (screens, trommels) are used in business operations when there is a need to sort material or clean it from contaminants and impurities. This is related not only to the high quality of raw material processing and productivity levels but also to their versatility in application.

Screening as a method for sorting material or cleaning it is widely used across many industrial sectors:

- Agriculture. The drum desoiler is used in the process of cleaning root crops (potatoes, beets, carrots, etc.) from excess soil. It is also used for cleaning compost or soils. It enables the screening of fertile soil layers from rock fragments, debris, and impurities.

- Construction. Screening is used for the separation of slag, crushed stone, gravel, sand, and other bulk materials.

- Coal and mining industry. Allows screening of bulk raw materials (coal, crushed stone, sand, etc.) by size fractions. When connected to an irrigation system, the drum screen effectively washes ore from silt or clay inclusions, gold-bearing sands from clay, and more.

- Woodworking industry. Drum screens are used to sieve wood processing waste.

- Municipal services. An advantage of using the separator is that it can serve as a key component in the screening, crushing, and sorting of industrial and household waste lines, or operate independently.

Classification of Screens for Trommels

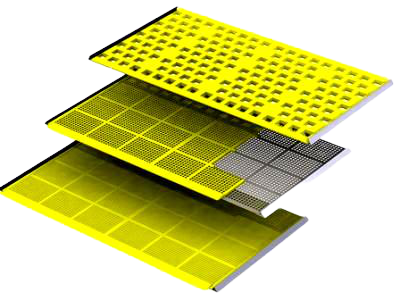

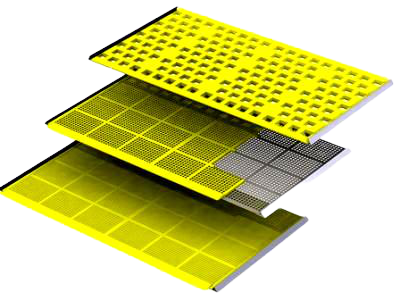

A screen is the main working component of an industrial trommel, serving as the sieving surface. A single unit may contain several screens. The efficiency and productivity of the screening process, as well as the lifespan of the screens themselves, depend on the correct selection of screens—including their design, size, hole shape, and the width-to-length ratio.

| Types of Screens for Trommels and Desoilers |

Image |

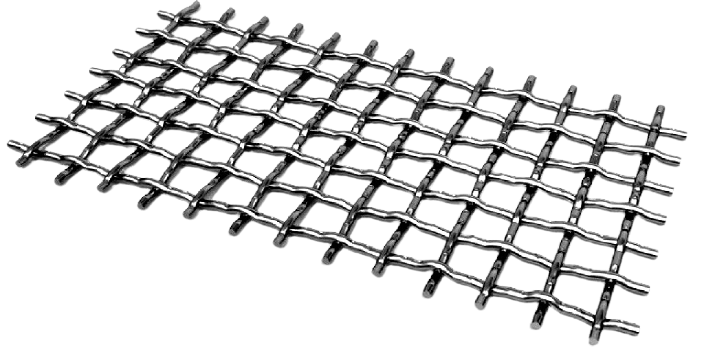

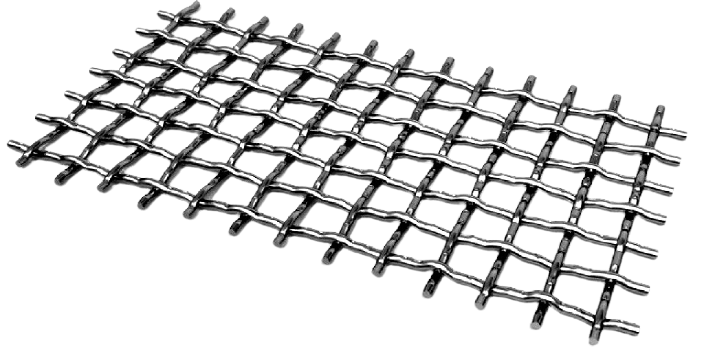

| Woven screens (the classic type of screens) have mesh openings of various shapes (square, rectangular, slotted). They are made from steel wire. The wire thickness for the screen is selected considering the size and density of the material to be screened. |

|

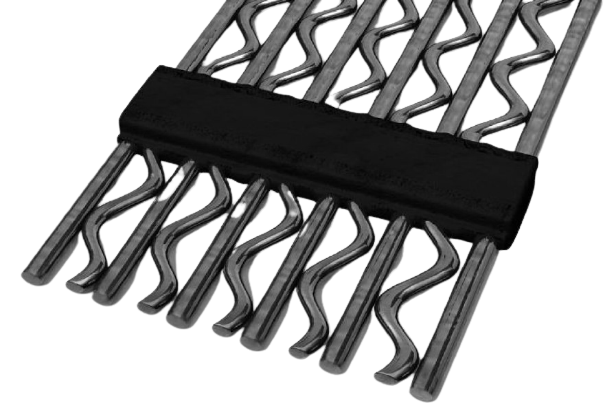

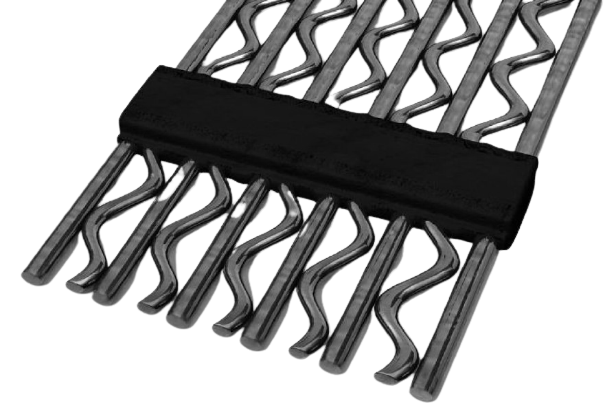

| Horizontal ribbed and combined wire screens. This type of screen is ideal for challenging screening conditions, especially for wet and clayey materials prone to sticking on the screening surface. They can be used for sorting materials with both flat and pointed shapes. |

|

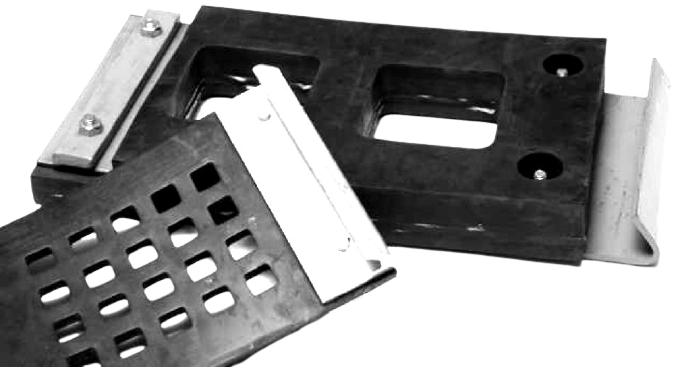

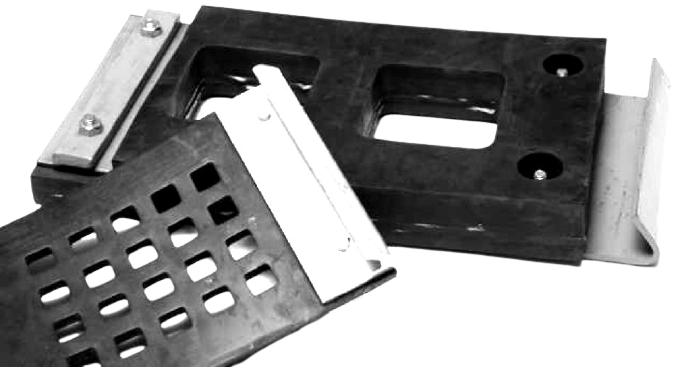

| Rubber screens. Screens of any size and shape, equipped with special fasteners on the sorting device, featuring various mesh sizes. These are used in special conditions such as hot screening, aggressive environments, as well as in the food and pharmaceutical industries. |

|

|

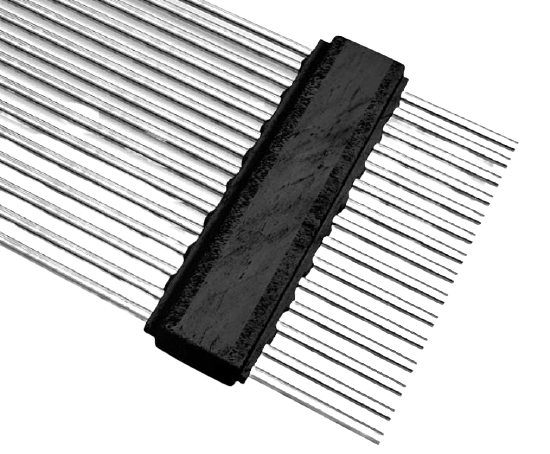

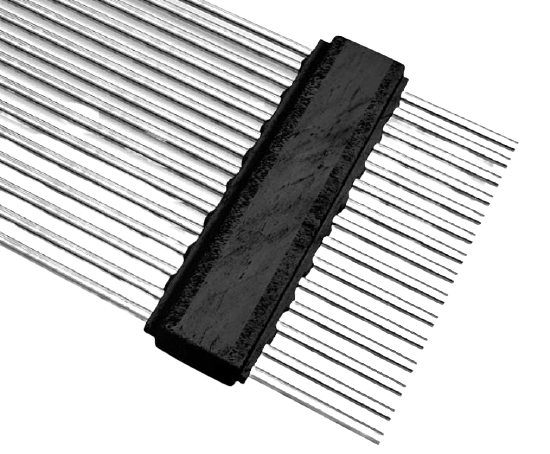

Wire screens (self-cleaning). Manufactured from carbon steel. The wire is attached around the drum (by welding or special fastening elements) at regular intervals (for example, for potato separation, wires are welded every 16 mm). They are distinguished by durability, simplicity, and lightweight design. Wire screens are ideal for separating root crops (potatoes, beets, carrots), gravel, and sand.

|

|

|

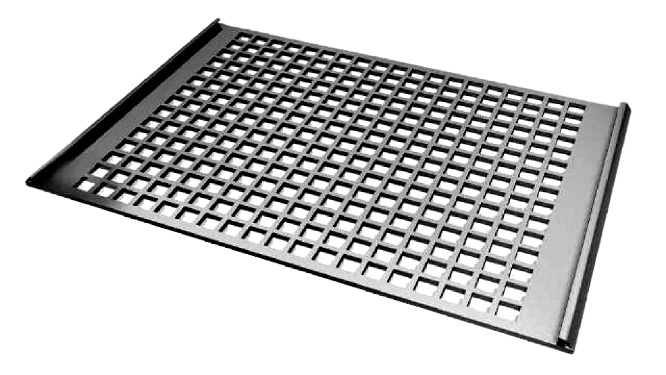

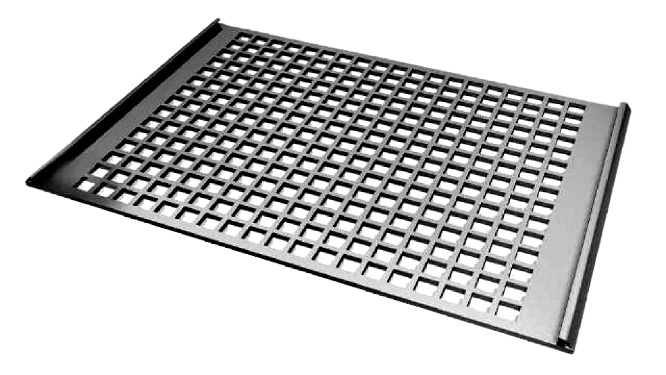

Metal perforated screens. Perforated screens are used for sieving non-metallic materials with fractions larger than 60 mm. They are made from steel sheets with a thickness ranging from 6 to 20 mm. Typically, screens with rectangular holes are used, but there are also versions with round and hexagonal holes.

|

|

|

Welded screens. Manufactured from steel rods with diameters ranging from 12 to 20 mm. Designed for sorting large volumes of bulk materials with a high degree of abrasiveness. They are most effective as top screens, as they can withstand significant impact loads. These screens are usually produced with mesh sizes ranging from 70 to 150 mm.

|

.png) |

| Polyurethane screens. The base material for manufacturing these products is plastic with a polyurethane base. To increase strength, the product is reinforced with metal cables, enhancing resistance to tearing and bending. They are used for screening materials with fractions from 0 to 120 mm. This type of screen is also employed for ultra-fine screening and dewatering applications. |

|

We offer our clients various configuration options for drum-type desoilers (screens, trommels):

- We manufacture both stationary and mobile screens (trommels). A mobile desoiler saves you money on transporting unwanted soil to storage, ensures cleaner vegetables at sale, and helps retain fertile soil in the fields;

- Additional equipment with belt conveyors and receiving hoppers at the input and output;

- Equipped with drive options from the central shaft (standard) or from the wheels;

- With various combinations or types of screens (wire mesh, polyurethane, perforated, or grate);

- With a washing system (spray devices based on nozzles) for wet screening;

- In the version with dust protection covers, with the possibility of connecting dust extraction equipment;

- With a single-sided or double-sided drum cleaning system (brush cleaners with electric drive) to improve the quality of sieve cleaning.

The desoiler, drum screener from BK "VIMALSPETSBUD" can be custom-made. We will help you choose the optimal solution tailored specifically to the needs of your enterprise for the most efficient operation of your production line.

We are located in Chernihiv and manufacture custom desoilers (screeners) according to customer requirements within the shortest time and at attractive prices. You can purchase desoilers (screeners) produced by BK "VIMALSPETSBUD" by placing an online order or contacting us by phone. (Go to contacts)

.png)