More detailed information on how to receive compensation when purchasing equipment from BK "VIMALSPETSBUD" can be found here.

he R-SORT receiving and sorting bunker from BK "VIMALSPETSBUD" provides a reliable foundation for product storage and sorting. It acts as a buffer, ensuring cleaning and, when necessary, sorting of your product by size.

Technical Specifications of the R-SORT Receiving and Sorting Bunker

| PARAMETER |

VALUE |

| Capacity |

up to 50 tons/hour |

| Receiving hopper volume |

10 m³ |

| Belt width of the hopper conveyor |

1800 mm |

| Discharge width |

3000 mm |

| Loading height into the hopper |

850 - 1050 mm |

| Conveyor speed of the hopper (adjustable) |

up to 3 m/min |

| Number of separation belt conveyors |

3 pcs |

| Width of the first separation conveyor |

800 mm |

| Width of the second and third separation conveyors |

600 mm |

| Speed of the belt conveyors |

16 m/min |

| Width of the separation section |

2000 mm |

| Distance between spiral rollers (first section) |

5 - 40 mm |

| Distance between spiral rollers (second section) |

5 - 90 mm |

| Number of spiral rollers |

14 pcs |

| Installed power (3-phase connection) |

8.5 kW

|

| Overall dimensions |

Value |

| Length |

6000 mm |

| Height |

2500 mm |

| Width |

3000 mm |

| Weight |

up to 4,500 kg |

Durable receiving bunkers are used for agricultural and industrial bulk materials such as potatoes, onions, carrots, and cocoa.

Cleaning and size sorting methods depend on your individual situation. Therefore, BC "VIMALSPETSBUD" offers various configuration options for the R-SORT receiving and sorting bunker, leaving you to choose the most suitable one for you and your production needs.

Operating principle and main components of the R-SORT receiving and sorting bunker from BC "VIMALSPETSBUD"

The loading container (receiving bunker) is filled with root crops using various transport methods. The receiving bunkers are durable and robust, capable of withstanding any load thanks to reinforced sides. The bunker is lined with rubber at points where root crops come into contact during unloading, ensuring gentle handling of the product (potatoes, beets, onions, carrots, and others) and protecting the structure from damage during discharge.

|

|

|

| Reinforced sides of the receiving bunker |

|

Rubber-coated housing of the receiving bunker |

Depending on the type of raw material and its intended use, different conveyor equipment is installed under the receiving bunker. Most commonly, belt conveyors with various types of conveyor belts (chevron, smooth, or rod) are used. The conveyor belt moves thanks to the rotational motion transmitted from an electric motor or gear motor to the drive drum.

|

|

|

| Receiving bunker with a belt conveyor (chevron belt) |

|

Product discharge point from the receiving bunker onto rollers

|

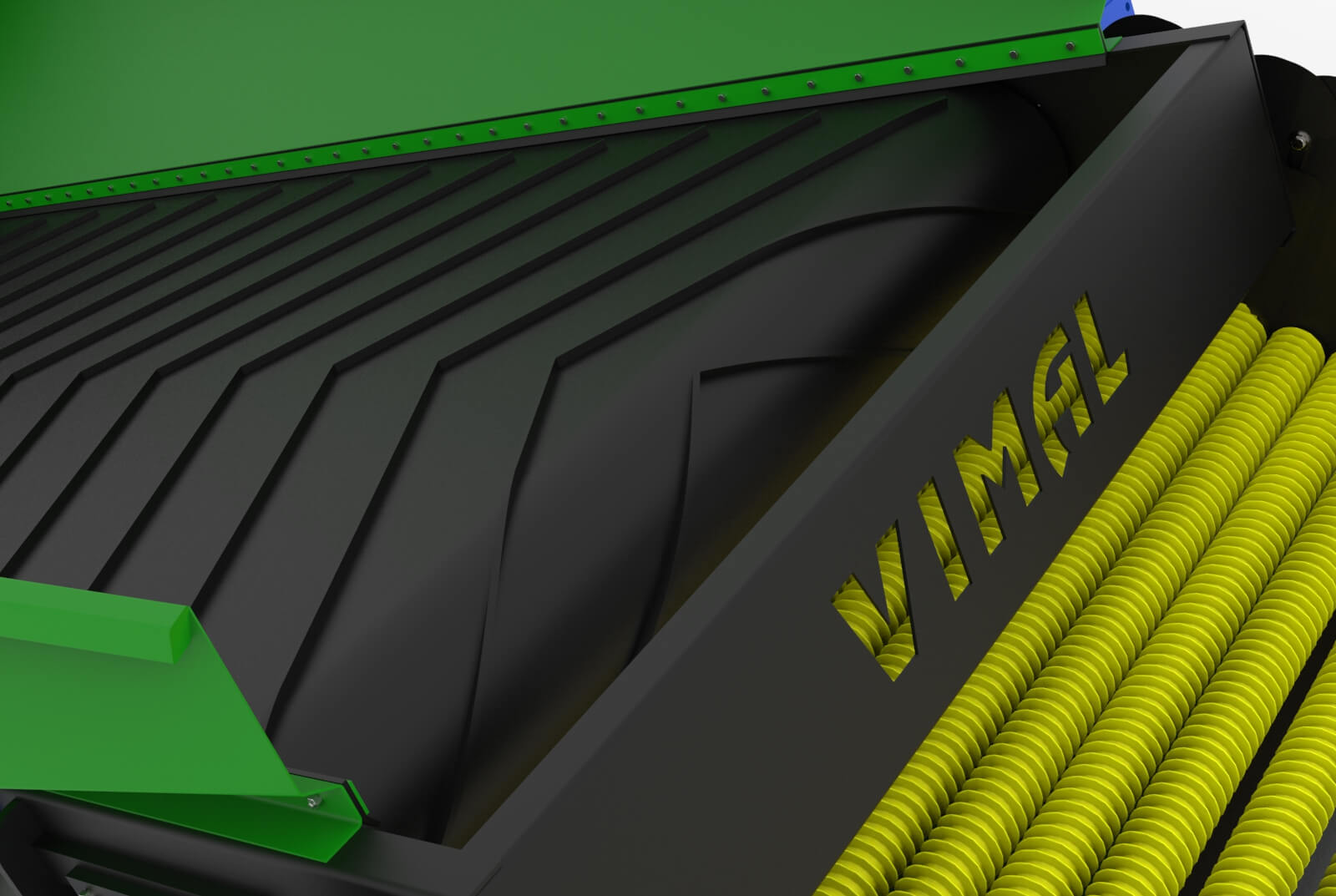

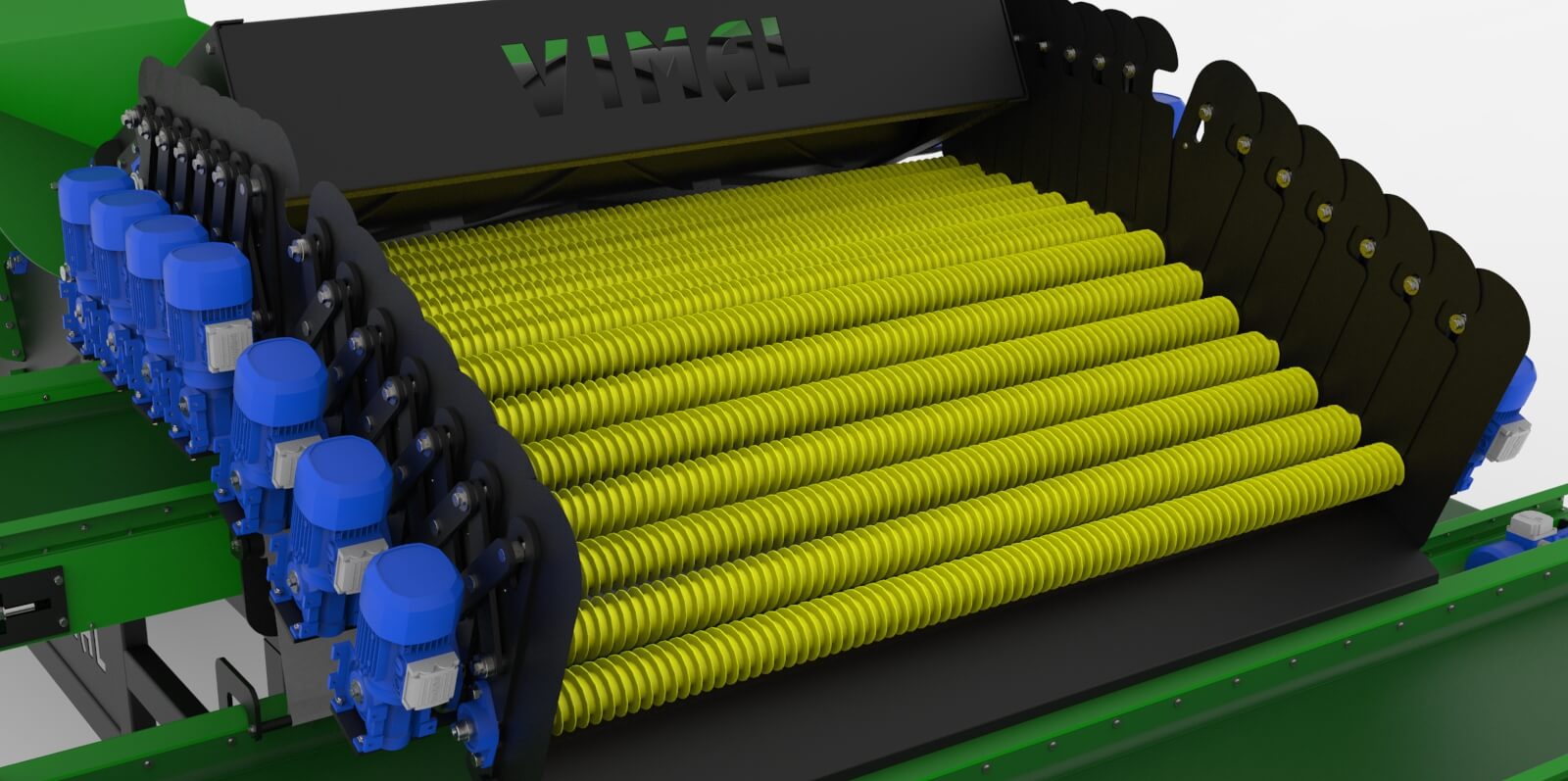

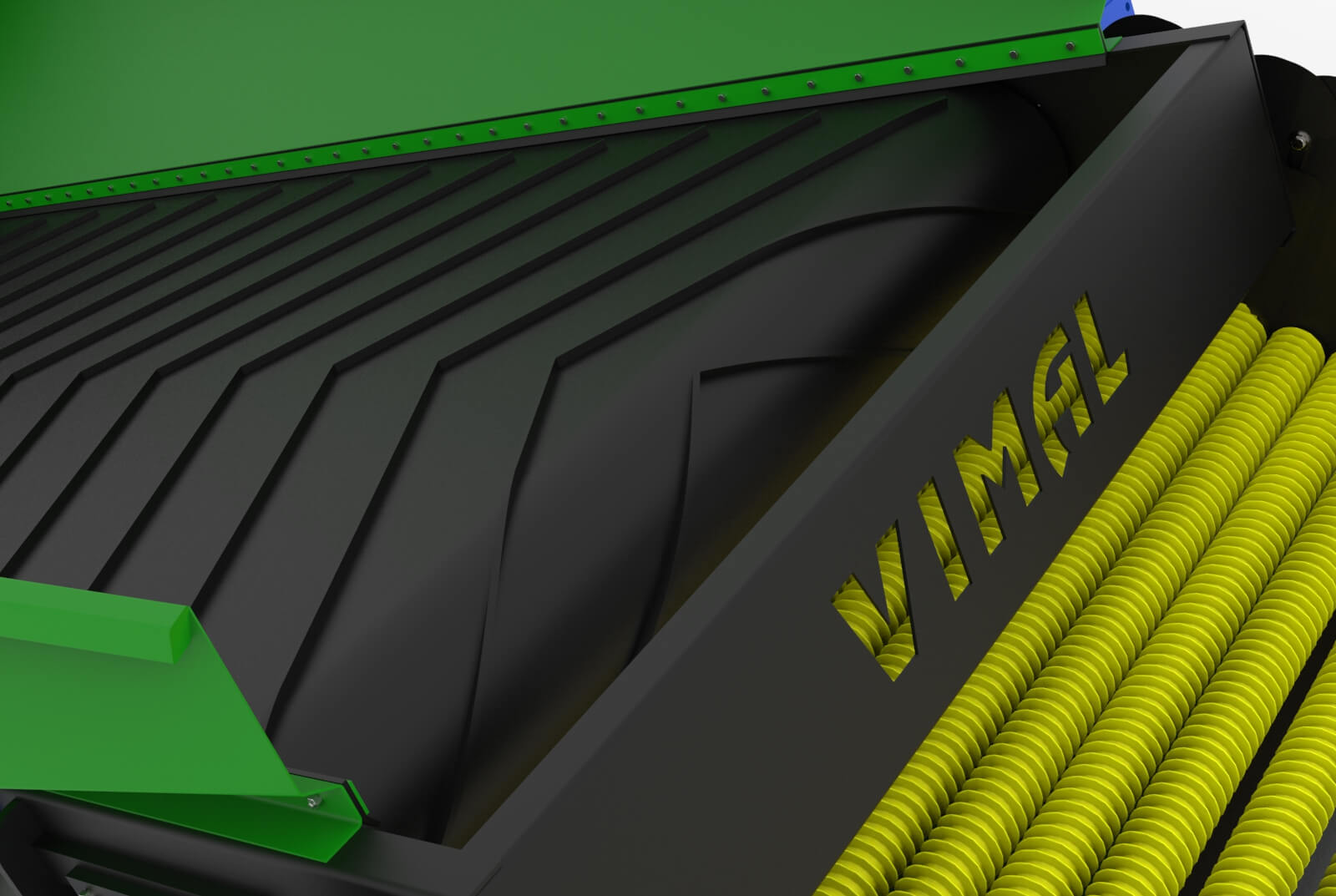

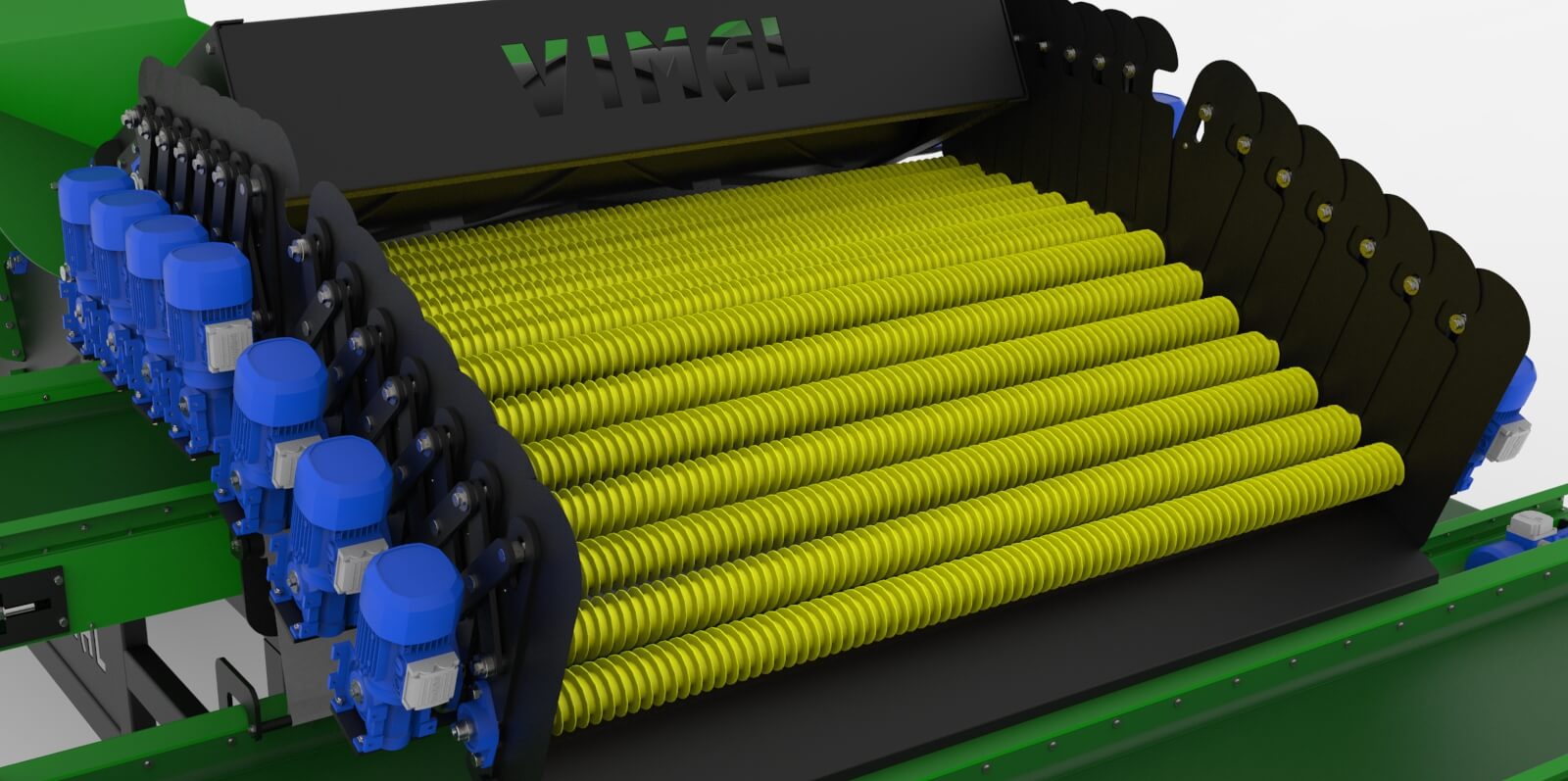

From the receiving section of the bunker, the product moves onto the cleaning spiral rollers, which ensure the gentlest possible handling of the product. A significant advantage is the independent hydraulic drive of each roller, providing long-lasting and uninterrupted operation. Independent control of roller groups allows achieving the best results for root crops of all sizes.

The special profile of the rollers prevents unwanted jamming of stones and clumps, as well as the winding of foliage between the spirals. The gap between the rollers and the inclination of the roller section can be individually adjusted to achieve optimal impurity separation. Instead of conventional chain drives, a direct hydraulic drive powers the rollers, significantly reducing the need for intensive maintenance.

|

|

|

| Independent hydraulic drive for each roller |

|

Hydraulic drive system for cleaning rollers |

After cleaning, the product moves to the next group of rollers where it is calibrated. The desired fraction size is achieved by continuously adjusting the spacing between the spiral rollers. Smaller-sized tubers fall through the gap between the rollers and are diverted sideways by a cross conveyor for the fine fraction, while larger-sized material continues along the rollers to the cross conveyor for the coarse fraction.

|

|

|

| Cleaning rollers with individual drive |

|

Three discharge belt conveyors |

Fast and precise size sorting will significantly boost the economic performance of your production. You can position the roller device either before the cleaning or size sorting stage, or directly after the receiving hopper.

Classification of cleaning rollers for the R-SORT receiving and sorting hopper:

- Spiral rollers. These rollers are suitable for various soil types, including rocky areas. Their enclosed design ensures superior cleaning without vines winding around the roller. Cleaning is always performed with maximum efficiency and without interruptions.

- Polyurethane rollers. As an alternative, polyurethane star-shaped rollers with 7 or 11 "fingers" are offered. They are suitable for removing light soil, providing effective cleaning while ensuring gentle handling of the product.

- Size sorting rollers. Size sorting rollers create square openings of a specific size at any adjustment. These rollers can only be used in combination with another type of roller. Scrapers can clean the rollers from adhered soil.

- Smooth rollers. These are smooth stainless steel tubes. The rollers are suitable for handling heavy soil. Under very harsh conditions, scrapers clean the rollers from adhered soil. They can also be combined with spiral rollers, and all rollers can be easily and quickly replaced.

The R-SORT receiving and sorting bunker from BC "VIMALSPETSBUD" not only captures attention with its excellent price-to-quality ratio but also impresses with its high productivity combined with minimal crop damage, alongside a multitude of innovative and practical solutions.

General technical specifications of the receiving and sorting bunker:

- The metal frame of the conveyor is coated with a durable, wear-resistant casing that prevents damage to the root crops, providing a "soft" bunker bottom.;

- The receiving hopper is treated with an anti-corrosion coating, ensuring the durability of the structure.;

- The conveyor drive is a motor-reducer;

- Stepless adjustable conveyor speed control;

- Any conveyor width, customized to your individual order;

- From 6 cleaning rollers with scrapers;

- Independent drive for each roller, ensuring long-lasting and uninterrupted operation;

- Possibility to adjust the distance between rollers (the spacing between rollers is mechanically set using a screw);

- Possibility to mechanically adjust the inclination of the roller assembly;

- Possible additional equipment with a belt conveyor for removing soil/product with movement to the right or left;

- Installation of a second belt conveyor behind the cleaning rollers is also possible;

- The working capacity of the hopper ranges from 4 to 21 m³ — customizable according to your individual order;

- The throughput capacity of the receiving and sorting hopper depends on the volume of your production and is made to order;

VIMALSPETSBUD manufactures both stationary and mobile receiving and sorting hoppers. The advantage of a mobile hopper is that you can install it wherever convenient and move it (thanks to the installed wheels) according to your industrial needs, unlike stationary hoppers, which cannot be relocated.

We are located in Chernihiv and manufacture R-SORT receiving and sorting hoppers to order, based on customer requirements, within the shortest possible time and at attractive prices. You can purchase R-SORT receiving and sorting hoppers produced by VIMALSPETSBUD by submitting an online application or contacting us by phone. (Go to contacts)