Driven rotary roller conveyors are roller conveyors that can change the direction of the moving objects. A rotary driven roller conveyor is used in a line when there is a need to make a turn while transporting goods or to bypass a column or machine.

Purpose of driven rotary roller conveyors:

The main purpose of this conveyor is automatic transportation, during which the direction of the cargo supply is changed, as well as its redirection to another room or equipment by navigating corners.

The conveyor is mainly used for transporting goods in warehouses (both for short and long distances), terminals, logistics centers, etc. With the help of the turning conveyor, the handling of oversized cargo is made easier in production, and the process of moving various types of cargo (such as pallets, packages, crates, buckets, etc.) across horizontal or vertical surfaces is also accelerated.

Turning driven roller conveyors from BK "VIMALSPETSBUD" have several advantages:

- Reliable construction and durable components;

- Ease of operation and maintenance;

- Cost-effectiveness;

- They have a minimal risk of damage during cargo transportation.;

- It is possible to monitor volumes, direction, as well as the nomenclature of the cargo..

The powered turn conveyor is most often equipped with a side guide because the angle of movement can be 45, 90, or even 180 degrees. This equipment is driven by an electric motor via a chain or belt drive.

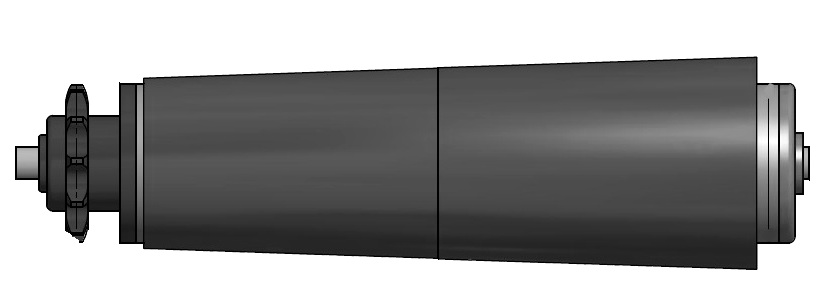

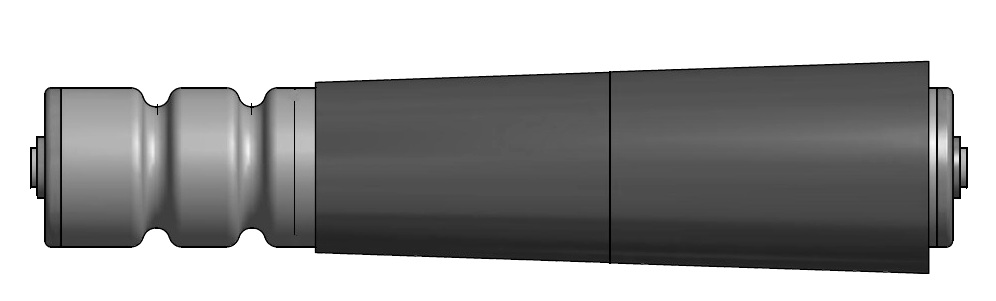

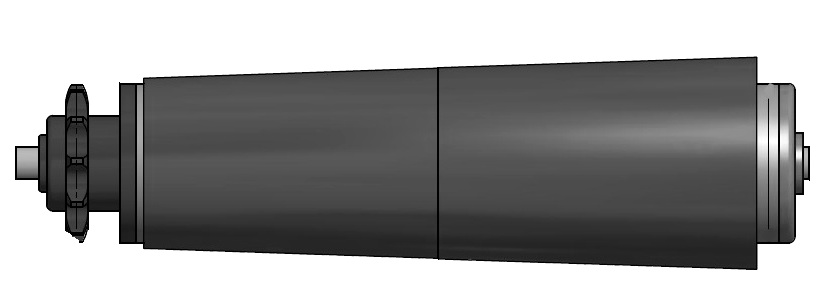

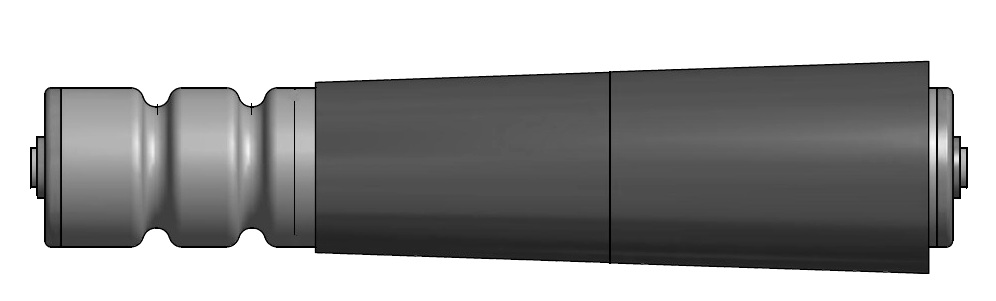

The rollers in turn conveyors have a conical shape, which allows maintaining a constant angular velocity of the moving load. In production, turn conveyors can perform individual tasks or be part of a production line. Crucial parameters include the roller pitch, turning radius, roller type, as well as its diameter, the material from which the roller is made, device width and height, type, speed, and power of the conveyor's drive unit.

Important! When choosing from a wide range of turn-driven roller conveyors, it is essential to consider the type of cargo you need to transport. Ideally, the length of the conveyor rollers should be wider than the cargo itself, and the distance between rollers should be less than half the length of the cargo.

Depending on the type of drive used in the roller conveyor, various types of tapered rollers are employed:

Drive tapered roller with sprocket. The roller is powered by a motor reducer through a chain drive. This allows the movement of heavy loads. The rollers come with either single or double flanges, enabling power transmission using a standard roller chain.

Drive tapered roller with pulleys. The drive roller (using a round belt) is used in roller conveyors where the load movement is transmitted from the roller. The roller is powered by a motor reducer through a distribution shaft with pulleys, and from the pulleys via belt transmission. A round belt is used for the belt drive. The belt cross-section diameter depends on the transmitted load and the roller diameter.

In some cases, the use of straight drive rollers is possible. It all depends on the roller conveyor's turning radius, the distance between the rollers themselves, and is tailored individually to the specific requirements of your production.

Turntable drive roller conveyors can be additionally equipped with the following components:

- receiving table;

- reverse function;

- control cabinet with "start", "stop", and "reverse" buttons;

- speed control – frequency inverter;

- emergency stop buttons for the conveyor;

- photoelectric sensors;

- remote control panel;

- protective side guards;

- wheels with brakes.

If your facility layout doesn’t allow for a complete straight conveyor system, or you need to bypass an obstacle or close a loop, then a powered turn roller conveyor is an essential component for your transport system. At the request of the customer, BK "VIMALSPETSBUD" will manufacture any modification promptly and at an affordable price.

We are located in Chernihiv and manufacture straight driven roller conveyors of any size to order, based on customer requirements, in the shortest possible time and at attractive prices. You can purchase straight driven roller conveyors produced by VIMALSPETSBUD by submitting an online application or contacting us by phone. (Go to contacts)