More detailed information about obtaining compensation when purchasing equipment from BK "VIMALSPETSBUD" is available here.

Introducing a new product from BK "VIMALSPETSBUD" — the TWIN SORT SC-10 (SLK-10) sorting complex for post-harvest potato processing.

TWIN SORT - is the result of our 28 years of experience, embodied in a simple yet highly efficient device designed for our work realities, combining European quality with a reasonable price

TWIN SORT - reliable, durable, simple, and convenient to operate and maintain.

The productivity of the TWIN SORT SC-10 (SLK-10) sorting complex meets the requirements of small and medium-sized farms (up to 10 tons per hour). The design is lightweight and stable, aided by small rubber wheels and support stands. The equipment can operate not only indoors but also outdoors, provided there is access to power supply. Workstations are enclosed with railings and equipped with a lighting system.

The TWIN SORT SC-10 sorting complex for post-harvest potato processing is designed to separate soil, plant debris, and other impurities, as well as diseased and damaged tubers from the bulk of potatoes. It sorts tubers into two fractions and unloads them into containers, crates, or receiving mechanisms of packaging machines.

The operating principle of the TWIN SORT SC-10 sorting complex is very simple and straightforward.

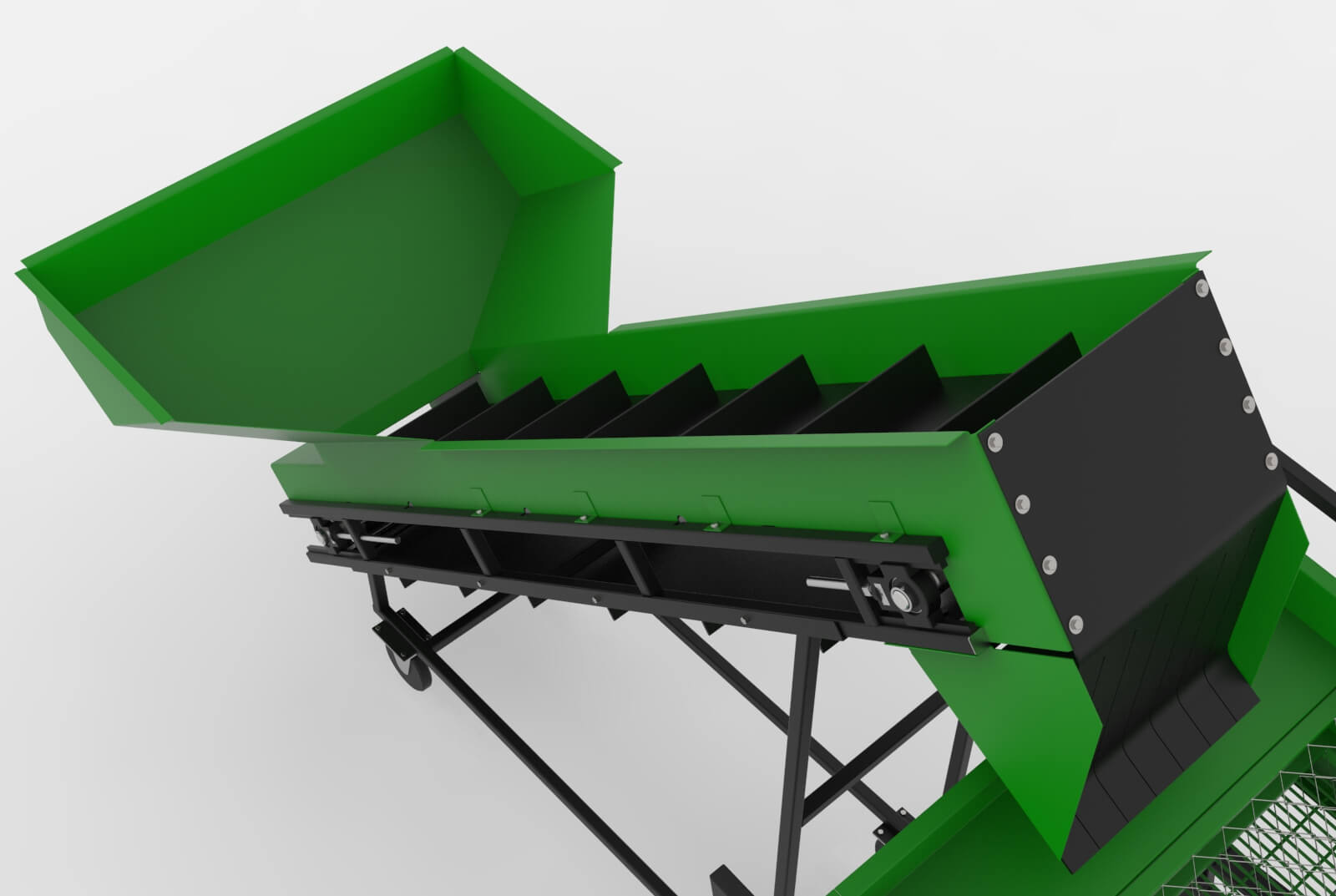

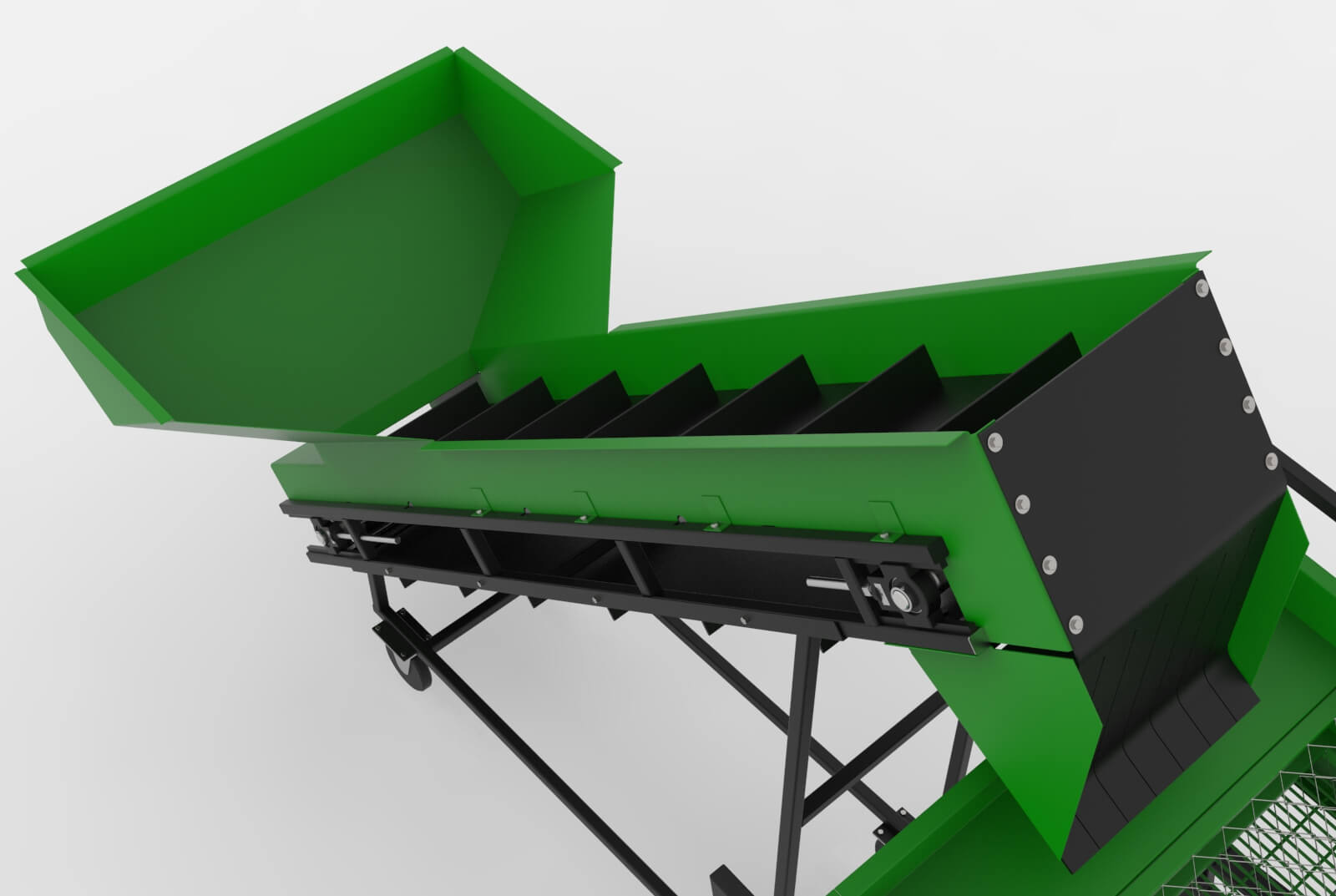

The raw material (root crops) is unloaded into the loading hopper (bunker) using various transport means, container tipplers, or manually, and then fed onto the conveyor. The loading conveyor with the receiving hopper delivers the potatoes onto the screens (sieves) of the potato sorting machine.

|

|

|

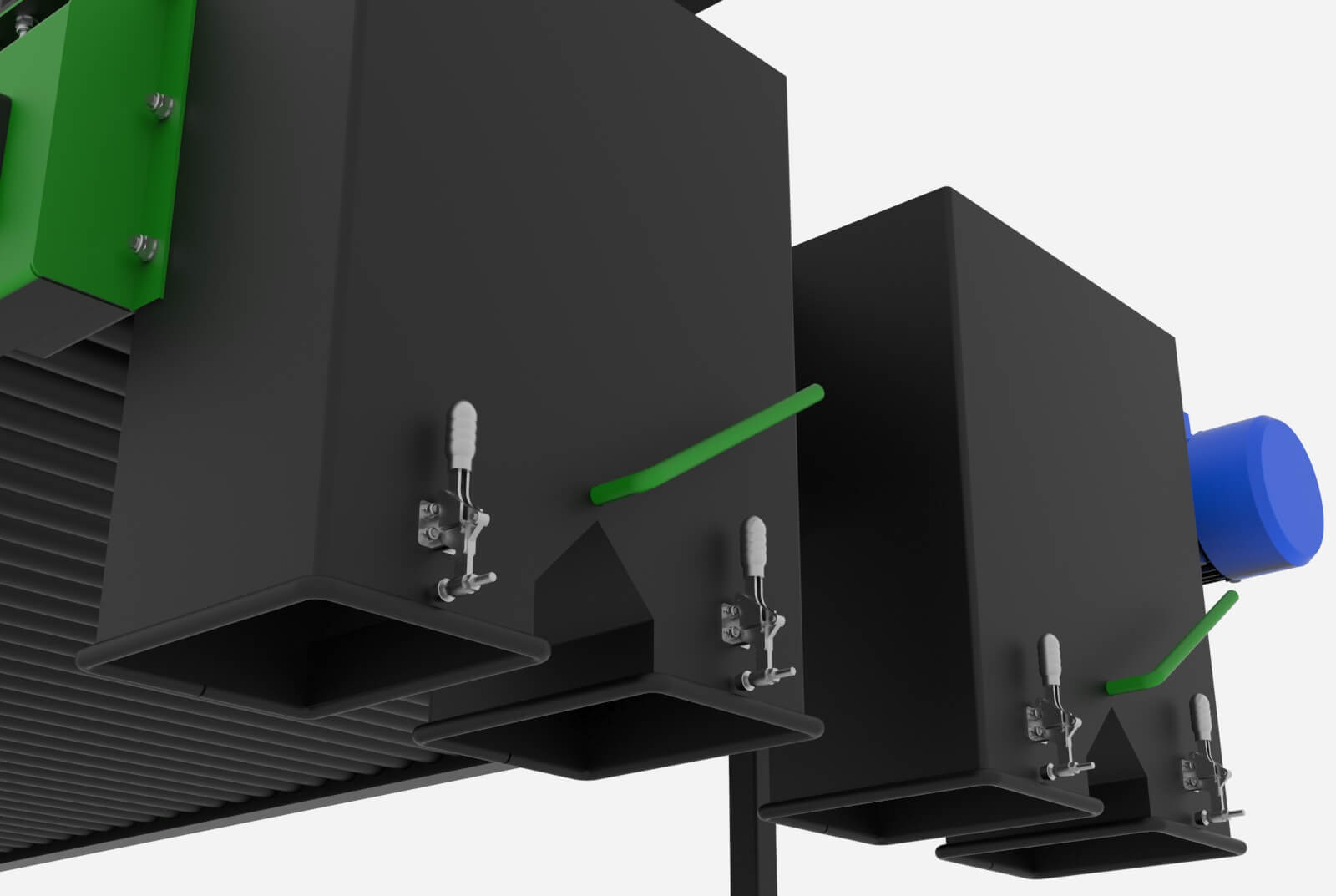

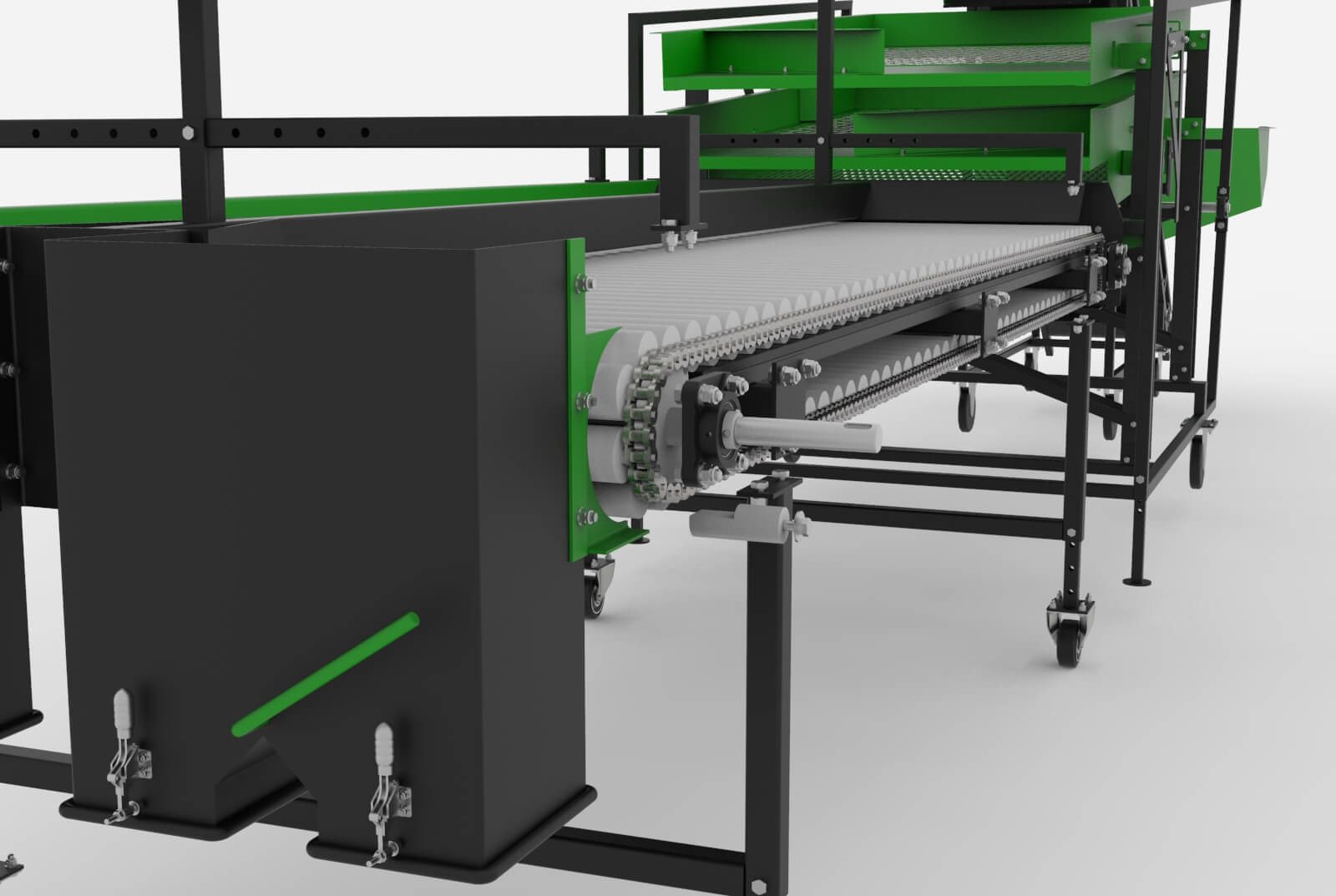

| Loading conveyor with receiving hopper |

|

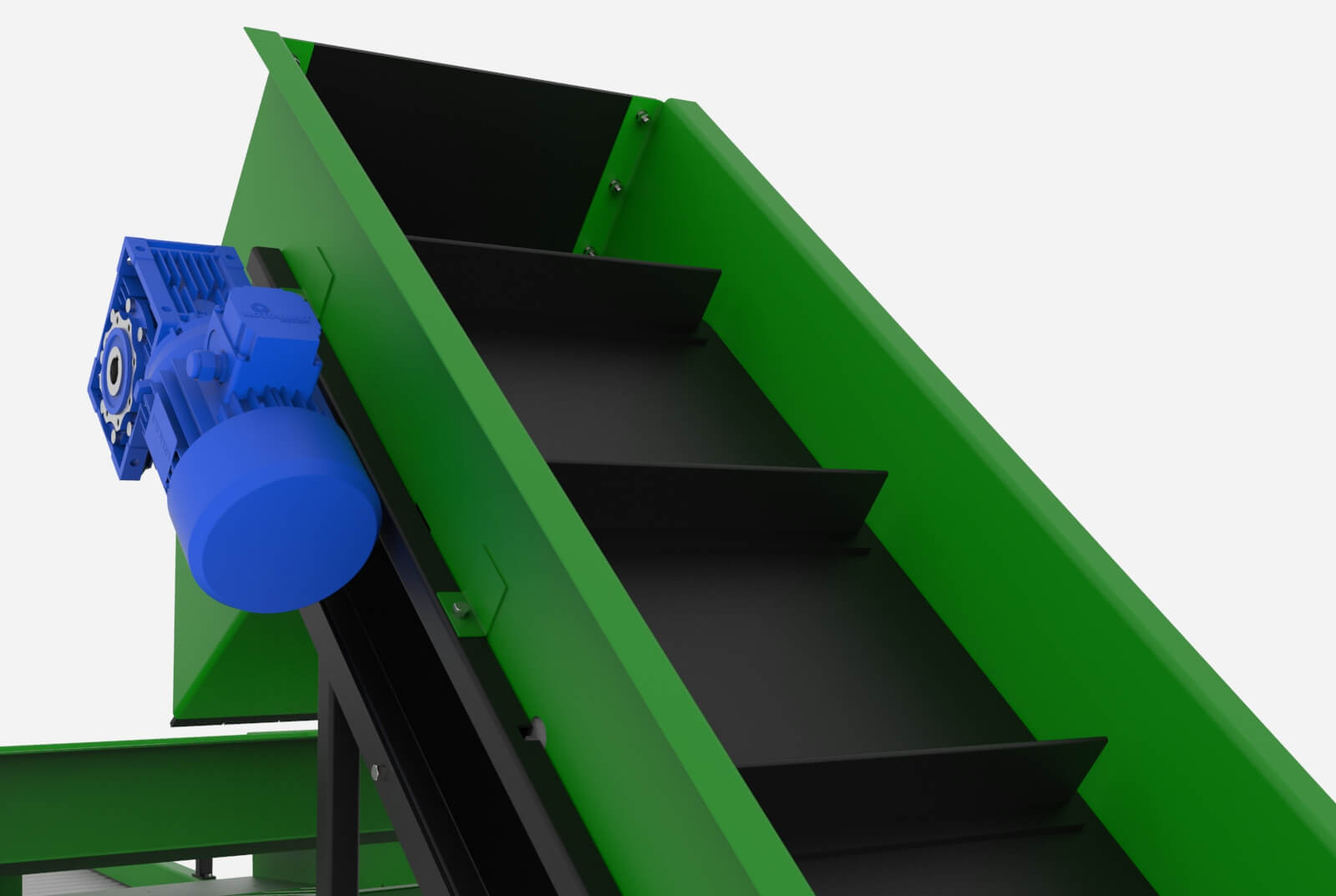

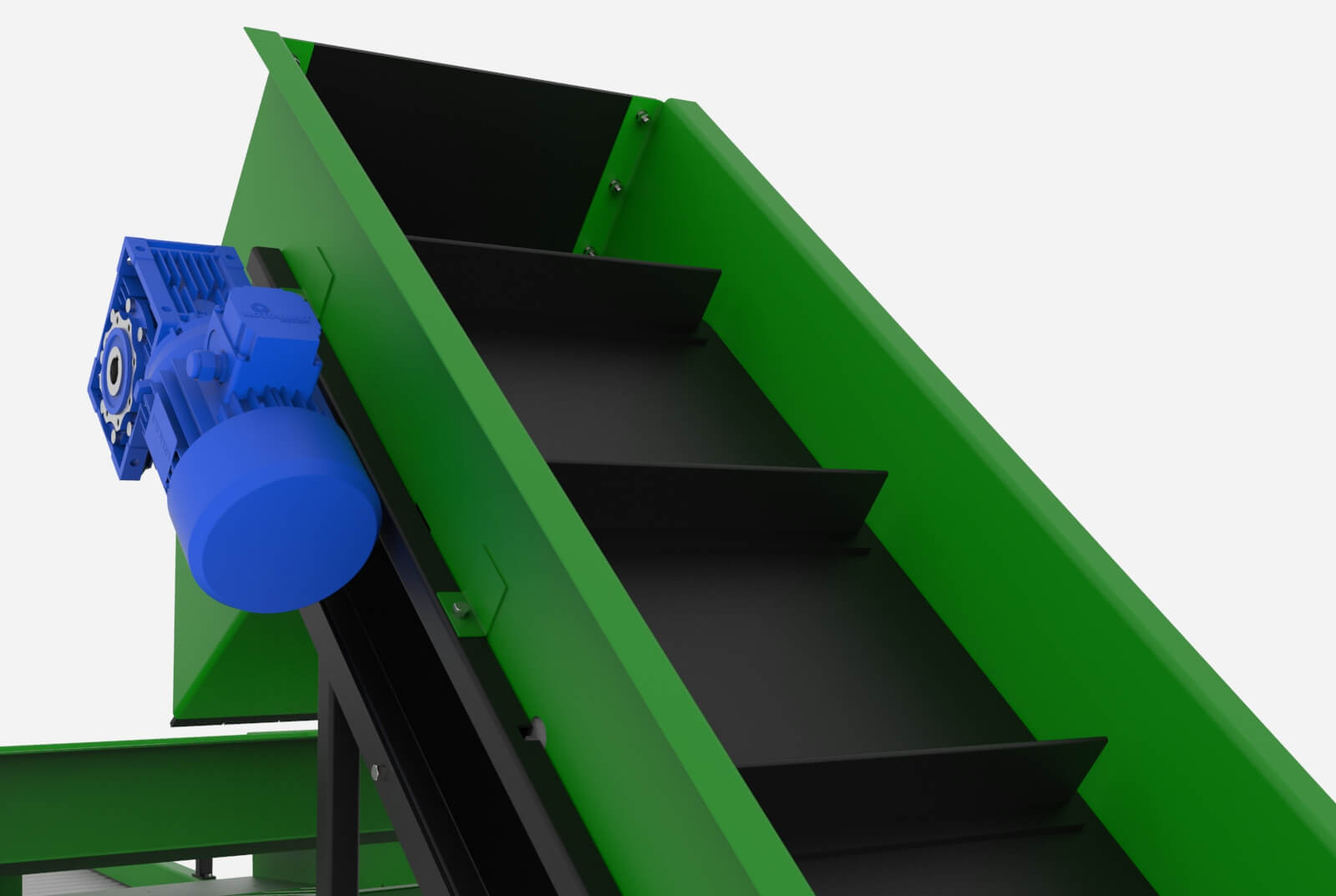

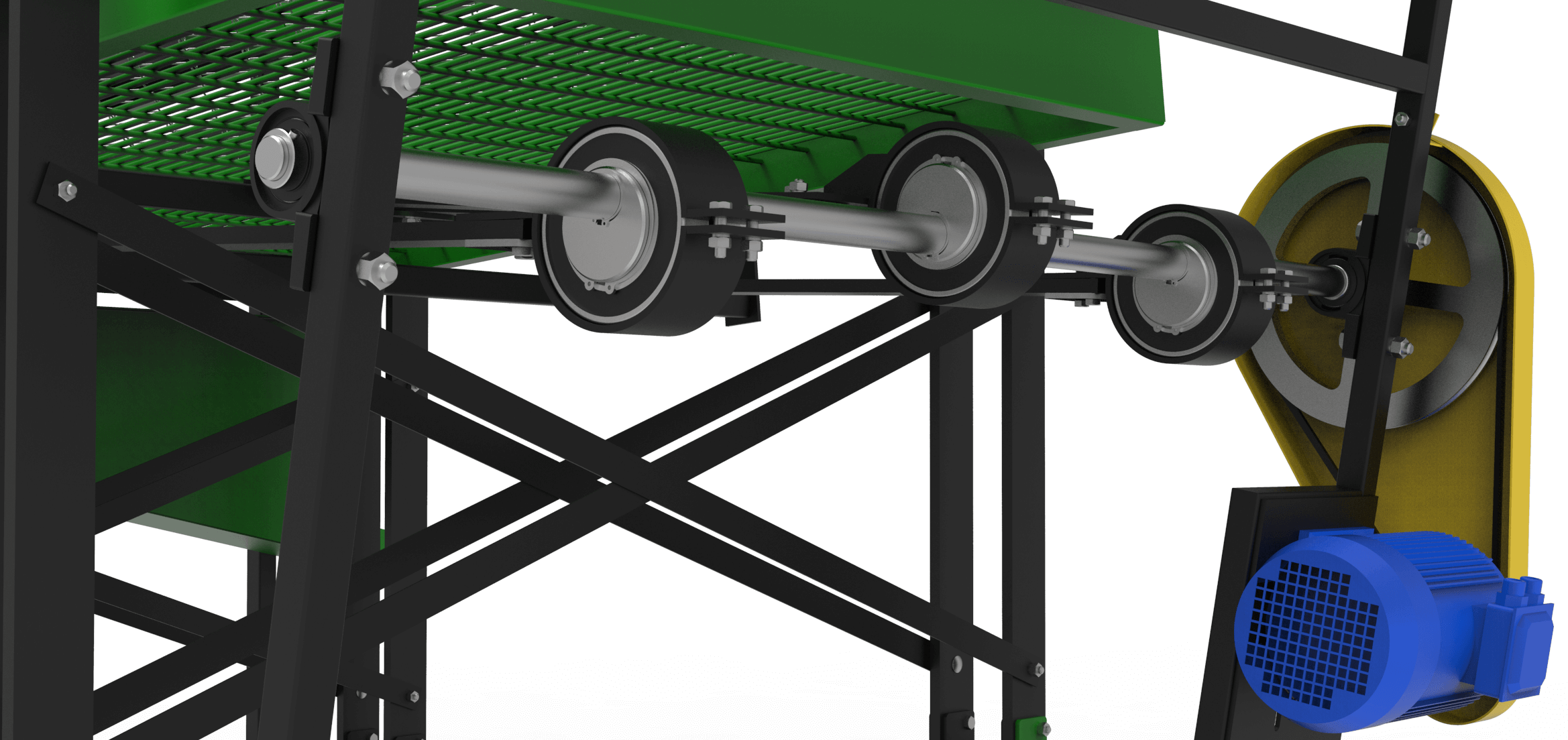

Drive of the receiving bunker conveyor |

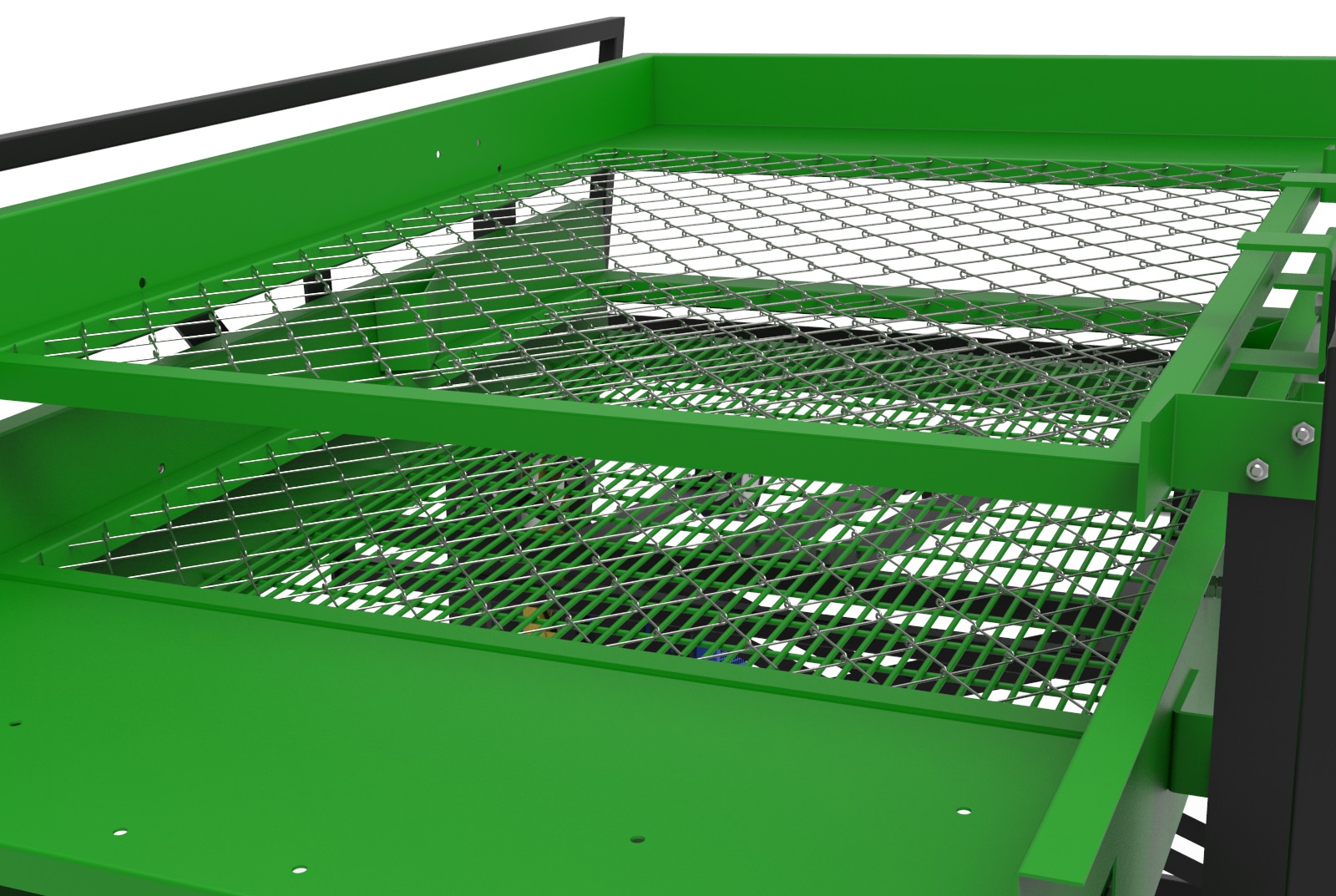

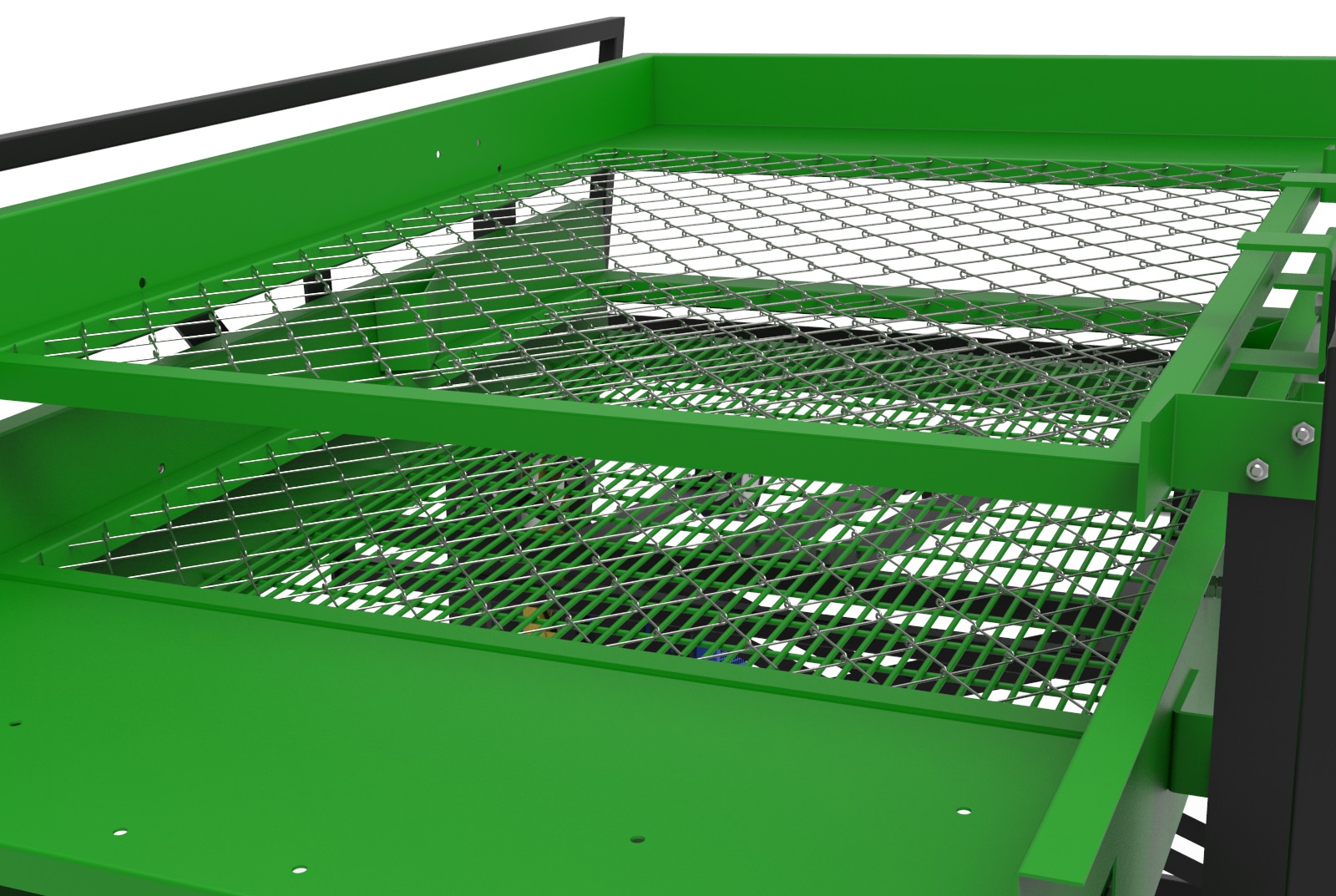

The potato sorter consists of two reciprocating sieve decks that allow sorting the potatoes into different fractions. Large and medium-sized potatoes (root crops) are directed onto the sorting table.

|

|

|

| Screens (sorting table sieves) |

|

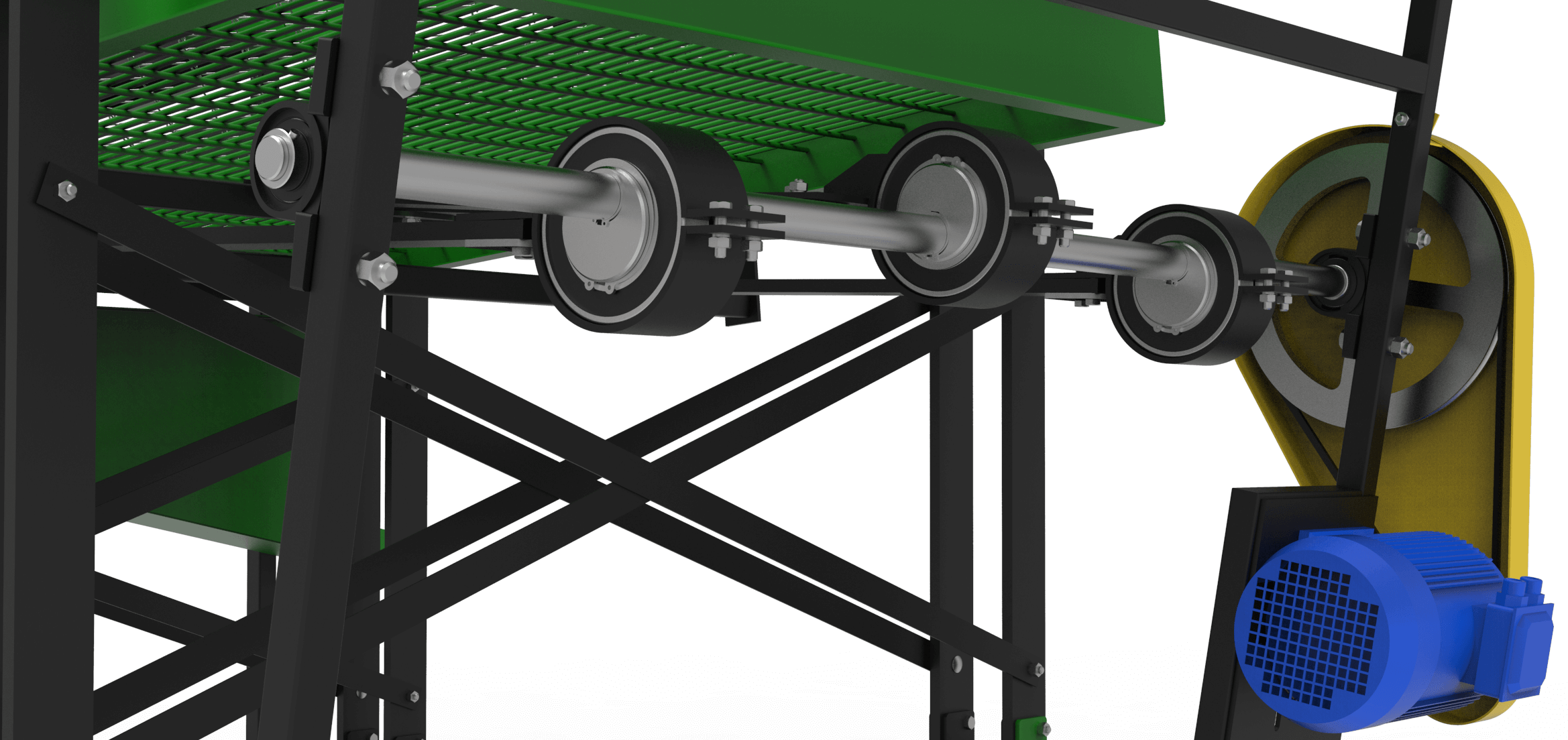

Operating principle of the sorter (reciprocating motion) |

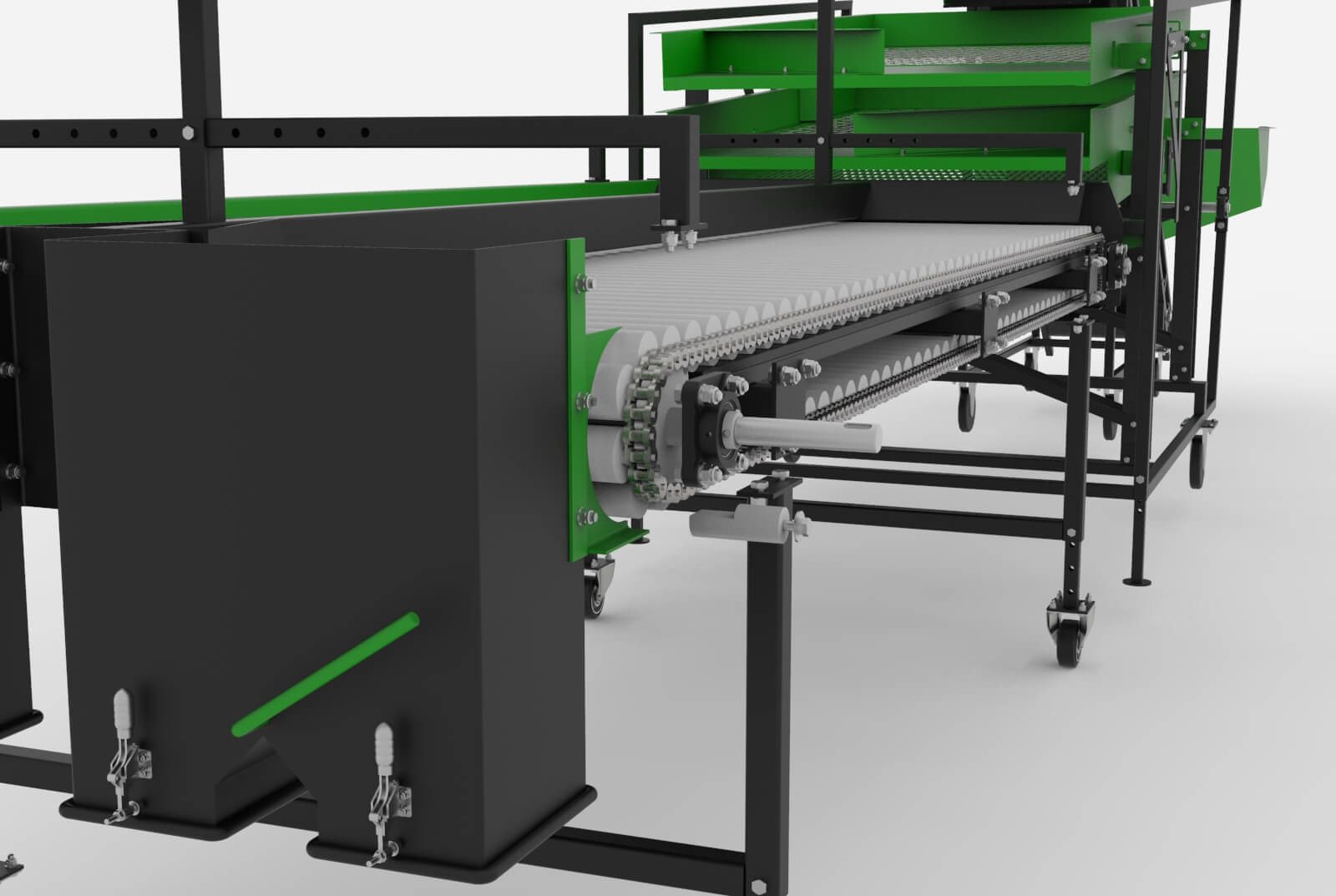

The sorting table consists of a powered roller conveyor (driven roller conveyor) divided by a splitter into two sections designed to receive the two main potato fractions (large and medium). It also allows for manual removal of damaged potatoes and stones. At the outlet, the table is equipped with four chutes, two for each fraction. Bags for packaging the sorted potatoes are attached to the chutes. The sorting table is equipped with a lighting lamp, enabling sorting work to be performed by personnel at any time of day.

|

|

|

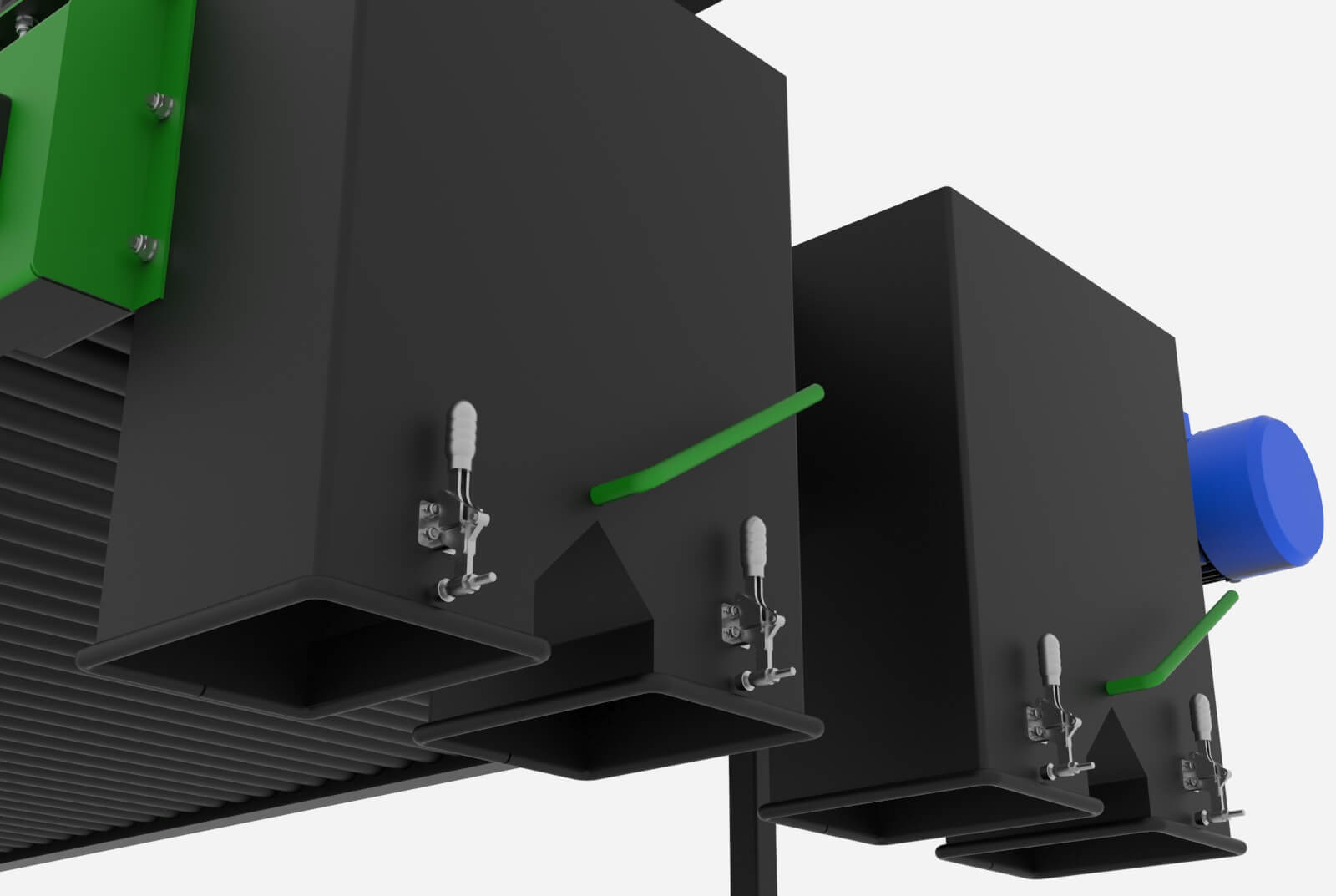

| Bag fastening outlets |

|

Inspection table (powered roller conveyor) |

Our sorting lines can implement the following set of technological tasks:

- Acceptance of raw materials directly from the side of transport vehicles;

- reception of raw materials in nets, containers of various sizes, and other types of reusable packaging;

- overturning of containers;

- smooth and even feeding of raw materials for processing using conveyors;

- dry cleaning of raw materials from easily separable soil;

- soaking and washing of raw materials with options for manual and automatic removal of contaminants;

- polishing of raw materials (treatment with stiff brushes to remove dirt in hard-to-reach areas, creating a marketable appearance before vacuum packaging);

- removal of droplets (pre-drying) from the surface of raw materials;

- complete drying of raw materials;

- inspection of raw materials and delivery to any point of the production area using an internal transportation system

- sorting of raw materials by diameter;

- packaging of raw materials in nets, vacuum packaging, and other packaging materials with simultaneous weighing, labeling, and many other technological capabilities.

The VIMAL Group of Companies has been working with potatoes for 28 years, and our engineers, more than anyone else, know exactly what is truly important for excellent equipment and meeting the client's needs!

We are also processors, and we offer you not just equipment — we provide you with a complete ready-made solution!

TWIN SORT can be custom-made to order. Our team of professional designers will help you choose the optimal solution tailored specifically to the needs of your enterprise, ensuring maximum efficiency and productivity.

We are located in Chernihiv and manufacture the TWIN SORT SC-10 (SLK-10) post-harvest sorting complex to order, based on customer requirements, within the shortest possible time and at competitive prices. You can purchase TWIN SORT equipment from VIMALSPETSBUD Construction Company by submitting an online application or contacting us by phone. (Go to contacts)