The RIT-10/25 Roller Inspection Table from BK "VIMALSPETSBUD" is designed for the inspection and manual sorting of substandard potatoes, beets, onions, and other vegetables. This machine can operate independently or as part of a pre-sale preparation line.

Construction and Operating Principle of the Roller Inspection Sorting Table from BK "VIMALSPETSBUD":

Main Components of the RIT-10/25 Roller Inspection Sorting Table:

- Steel frame with adjustable supports;

- Drive and tension shafts;

- Rollers;

- Gear motor;

- Lighting fixture, control panel, and tray

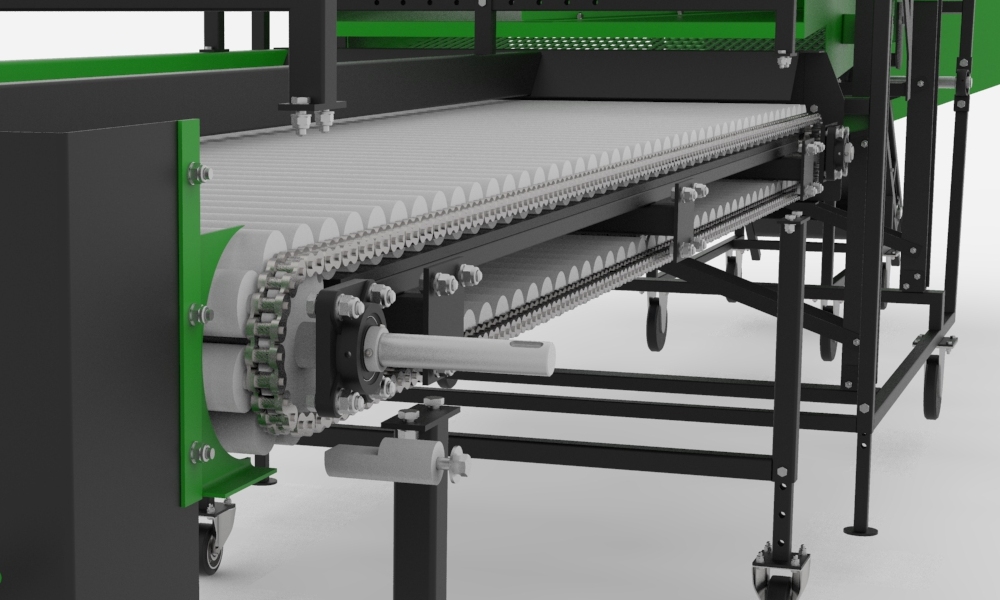

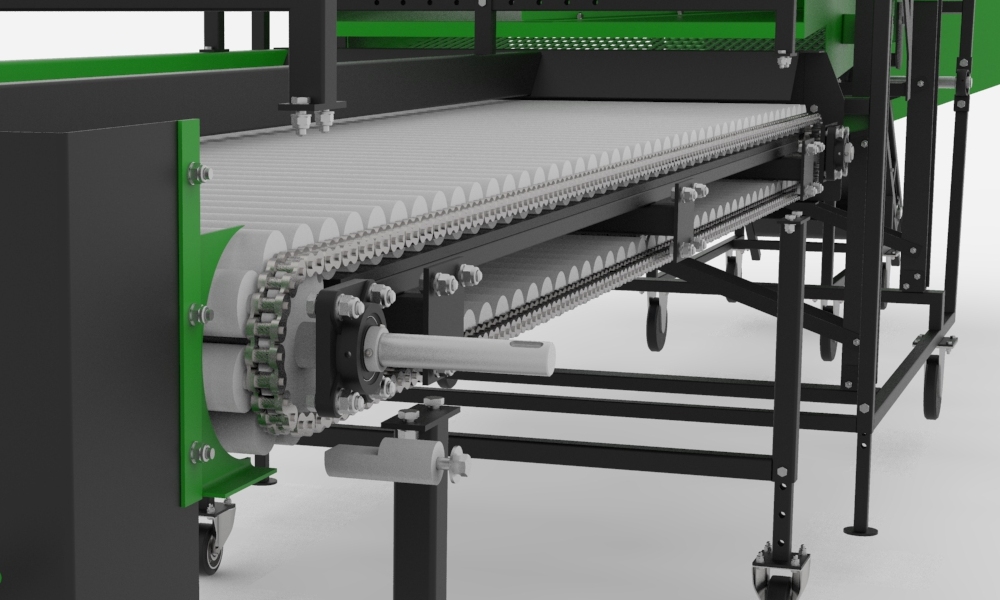

The inspection table from BK "VIMALSPETSBUD" features a steel welded frame with adjustable supports. The frame houses drive and tension shafts rotating in bearing units. Sprockets mounted on these shafts drive a roller conveyor consisting of a chain and rollers. The rollers run along a rubber profile. The drive shaft is powered by a gear motor. The frame also includes a mount for the divider and a lighting fixture. Additionally, a control panel and a tray for product removal from the work area are installed on the frame.

|

|

|

| Roller conveyor belt (chains and rollers) |

|

Frame with divider and lighting |

Principle of operation of the inspection table

The machine operates as follows: inspected vegetables (product) are fed by conveyor, hopper, or other equipment onto the roller bed at the rear of the machine. The roller bed moves the vegetables along the machine while rotating them, ensuring inspection from all sides. A divider splits the working roller area widthwise into three sections, dividing one product stream into two on either side of the machine. The middle section serves to remove non-conforming products. The inspected product is transported to a chute, where it is removed from the working area. Non-conforming products separated from the main stream are also conveyed to a chute and fall down into a special pocket. The machine can be equipped with a chute for manual packing of products into nets or other soft containers.

| Specifications |

Values |

| Performance (depending on fraction and condition) |

up to 10 tons/hour |

| Working area length / width |

2500 / 1000 mm |

| Roller diameter |

50 mm |

| Roller speed (adjustable by frequency converter) |

Up to 0.24 m/s |

| Installed power |

0.55 kW |

| Power supply |

400 V / 50 Hz |

| Weight |

375 kg |

Improper use of equipment is unacceptable if:

- Electrical power connection is made in violation of regulations;

- The socket for connecting the machine lacks grounding;

- The equipment is placed in an unstable position;

- Do not perform repair or maintenance work on the control panel and electric drive without first disconnecting the machine from the power supply; there is a real risk of electric shock;

- If unusual noises, knocks, or vibrations appear during the test start or operation of the machine — immediately stop work and have the equipment inspected by qualified personnel;

- If cracks are detected in parts or assemblies of the machine, or if there is oil leakage through the motor-reducer seals, immediately stop operation and arrange for professional maintenance or repair to prevent further damage and ensure safety.

Installation, adjustment, and preparation for operation

The equipment is installed on a flat, solid surface, resting on all four supports (legs) and secured against accidental movement by locking two wheels with a built-in brake.

Before starting operation, the following checks are performed: integrity of machine parts and assemblies, tightening of threaded connections, compliance of the power supply parameters with the machine's electrical equipment specifications, direction of roller belt movement, and its tension.

We are located in Chernihiv and manufacture the RIT-10/25 inspection sorting table to order, tailored to customer requirements, with the shortest lead times and attractive prices. You can purchase the RIT-10/25 inspection sorting table produced by BK "VIMALSPETSBUD" by submitting an online application or by contacting us by phone. (Go to contacts)