A screw conveyor (auger conveyor) is a versatile transporting device that operates continuously and ensures the movement of various bulk, powdered, fine-fraction, and dust-like materials. The screw conveyor is primarily used in:

- the food and agricultural industries (transporting grain, flour, starch, food mixtures, compound feed, and others);

- glass industry;

- chemical industry (where the full sealing of the trough allows for the safe transportation of aggressive substances);

- mining and construction industries (transportation of cement, sand, coal dust, chalk, gypsum, and other powdered and low-abrasive materials);

- used in enterprises as a dispenser or mixer.

VIMALSPETSBUD represents high-quality products proven over the years. Our production is built on professionalism and strict control at every stage. We continuously work on improving our products while reducing their manufacturing costs.

Main structural components and operating principle of the screw conveyor from VIMALSPETSBUD:

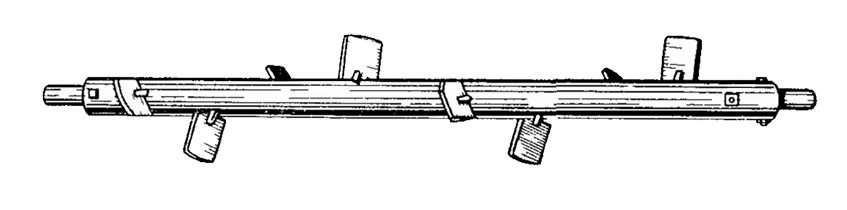

- Screw conveyor housing: the screw conveyor can be either open or closed, which determines its basic shape;

- Intake section for product (material) or hopper. The presence and volume can vary according to the customer's requirements;

- Drive screw (various screw configurations available, allowing customization of the conveyor to meet the specific needs of your production);

- Electric motor that drives the screw (auger) into motion;

- Discharge outlets of various shapes (square, rectangular, circular).

The screw conveyor is often installed in environments with challenging conditions: high humidity, low temperatures, and air saturated with dust and fine solid particles. Therefore, if you purchase a screw conveyor, it is essential to ensure proper installation of the unit in your production facility or outdoors.

The structure consists of a trough equipped with several loading sections. Inside the trough, there is a screw, with the load positioned between its blades. Rotation is transmitted to the screw by a drive system, causing the load to move along the trough and be directed toward the discharge outlets at the end of the line.

Types of screws (augers) used in conveyors

The screw is the most important component of the entire equipment. Different types of screw conveyors are used depending on the material being handled.

| Types of screws (augers) used in conveyors |

Rotation frequency |

Image |

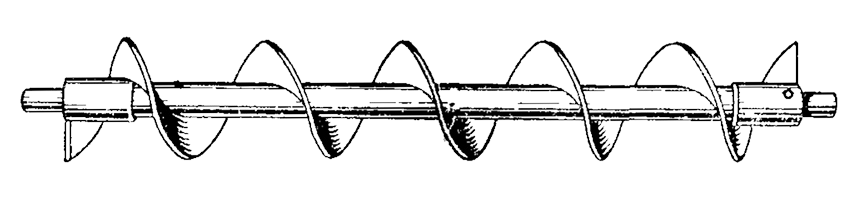

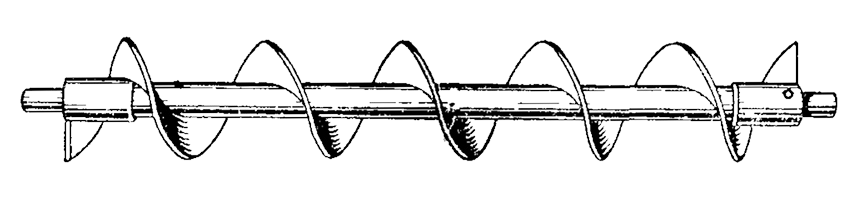

| Solid screw. It is stamped from sheet steel, then individual elements are closely mounted on a tubular shaft. It represents a continuous spiral. Used for grain and for transporting powdery, fine-grained, medium-sized, dry materials that do not tend to clump. These can include chalk, gypsum, ash, dry sand, small-fraction slag, cement, etc. |

50 - 120 rpm |

|

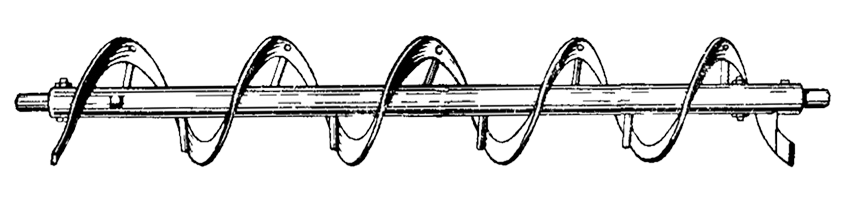

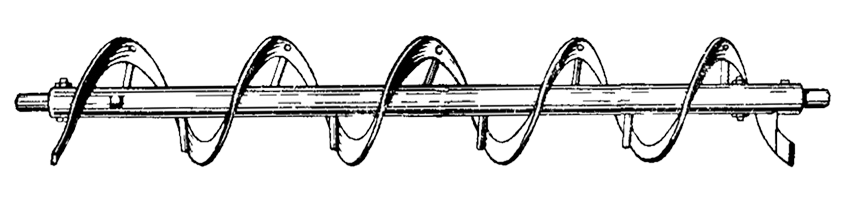

| Ribbon screw. Made from a metal spiral strip, it is mounted on a shaft with a gap between the inner edge and the shaft. This gap allows the material to roll back over the spiral, promoting mixing as it moves through the screw conveyor. Used for transporting bulk materials such as gravel, limestone, sandstone, and ungranulated slag. |

40 - 100 rpm |

|

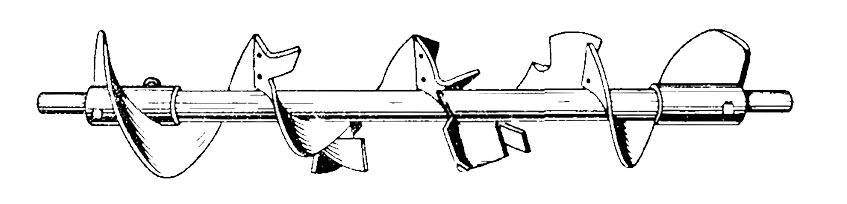

| Shaped (profiled) screw is used when handling wet clay, cement mortar, concrete, and other wet or cohesive materials. |

30 - 60 rpm |

|

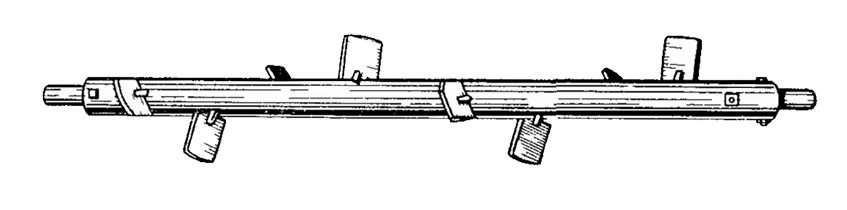

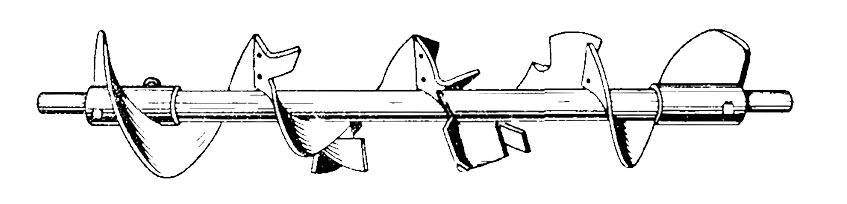

| Blade screw consists of separate blades mounted on a shaft at calculated intervals. It performs several functions simultaneously: mixing, loosening, and transporting the material. This type of equipment can handle two types of materials: bulk (chunky) and wet (dough-like) substances. |

Chunky materials: 40-100 rpm |

Wet materials: 30-60 rpm |

|

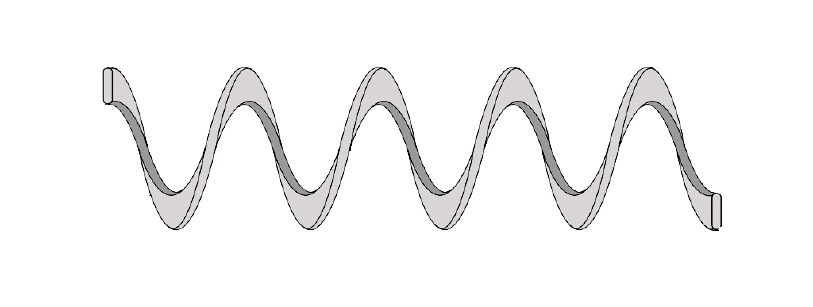

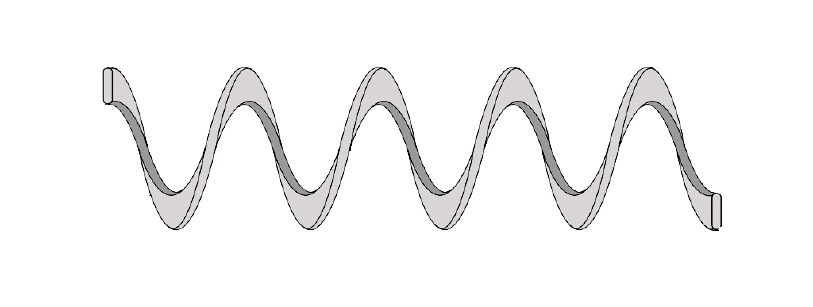

| Tubeless screw (spiral, flexible, spring-type). The main advantage of conveyors with a flexible spiral is that they allow material to be conveyed at inclines and around bends. |

250 rpm |

|

Important!

Despite its simple yet reliable design and ease of operation, many end users overlook crucial factors that can potentially lead to reduced productivity, excessive energy consumption, serious wear, and deterioration in material quality. For these reasons, it is essential to consider all system parameters when selecting conveyor options. Only by doing so can you ensure a proper and successful installation that guarantees maximum operational efficiency.

Design Features of Screw Conveyors:

- The screw (auger) flights are typically stamped from individual segmented discs. Usually, steel is used, but cast iron may be employed when transporting abrasive materials. This makes the main shaft much stronger but significantly increases the cost of the screw conveyor, so steel components are more commonly installed in the equipment.

- The central part of the screw is a tubular shaft, usually composed of individual sections measuring 2 to 4 meters in length. The screw blades are attached to its surface. At the ends, the shaft rests on bearings that are mounted internally on the end sections of the trough;

- The trough of the screw conveyor is also assembled from small sections. The material used is sheet steel. It can be either rounded or rectangular in shape. To reduce friction in the mechanism, a gap of approximately 6-10 mm is maintained between the trough wall and the screw;

- Our equipment is built using modern technologies, which is why we incorporate rolling bearings in the design. Their advantages include protecting the internal cavity from dust and dirt ingress, simplifying equipment maintenance, and ensuring a long service life of the device.;

- Loading and unloading points are equipped with funnels. Windows are cut in the cover and the bottom of the housing, to which outlet pipes are then attached. These pipes may be fitted with either toothed or standard gates.;

- The screw rotation is powered by an electric motor. The drive in a screw conveyor can be belt-driven or use a gearbox. Typically, the transmission mechanism is located at the end section of the housing.

Advantages of the Screw Conveyor from BK "VIMALSPETSBUD":

- Simple and reliable design;

- Ability to position the trough at angles up to 60 degrees;

- Controlled material feeding;

- Possibility of intermediate material discharge;

- Airtightness;

- Safety ensured by full isolation of moving parts with a protective casing;

- Competitive price compared to other types of conveyors.

We are located in Chernihiv and manufacture straight driven roller conveyors of any size to order, based on customer requirements, in the shortest possible time and at attractive prices. You can purchase straight driven roller conveyors produced by VIMALSPETSBUD by submitting an online application or contacting us by phone. (Go to contacts)