Turning is the machining process of cutting external and internal rotating bodies. The most common workpieces are bolts and nuts, shafts, and axles. It is one of the oldest mechanized technical processes.

Turning is a type of mechanical processing aimed at giving the finished metal piece the required shape or even pattern. During this process, the workpiece often rotates on a special lathe while the turner shapes it to achieve both an attractive appearance and functional quality.

Turning work is a popular technology that allows manufacturing various metal products of different sizes, shapes, and structures—from small parts to complex components—according to customer drawings. The choice of metalworking machine depends on the dimensions, shape, weight, and complexity of the parts being processed.

Typically, lathe operations include:

- Cutting parts into different sections;

- Drilling holes;

- Thread cutting;

- Grooving.

Metalworking services performed by BK "VIMALSPETSBUD"

|

|

|

|

|

| Turning of internal and external threads |

|

Machining of slots and grooves |

|

Drilling holes, reaming, and countersinking |

|

|

|

|

|

| Machining of internal and external surfaces of parts |

|

Blank preparation |

|

End face and step sharpening |

Types of turning work:

- Turning external cylindrical, conical, and shaped surfaces;

- Boring internal cylindrical, conical, and shaped surfaces;

- Facing of ends and shoulders;

- Cutting off;

- Machining shaped surfaces using profile cutters;

- Cutting external and internal threads;

- External and internal grooves, fillets, chamfers;

- Knurling;

- And more.

It should be noted that all the above operations can be performed using CNC machines. This is especially efficient for serial production of parts where high precision and manufacturing speed are required, as well as for producing parts with highly complex profiles, shaped, and other types of surfaces that are difficult to produce on manual machines. Our engineers are ready to provide services for integrating such parts into production (i.e., developing a virtual 3D model of the required part, considering all features and manufacturing nuances, simulating mechanical, physical, and thermal resistance tests, and calculating optimal parameters to save significantly on materials and manufacturing time). This approach maximizes automation, eliminates human error, lowers production costs, and improves product quality.

Our experienced specialists perform turning work according to drawings or customer samples with constant quality control.

Currently, the enterprise operates the following turning and screw-cutting machines:

This allows machining workpieces with diameters up to 600 mm and lengths up to 2500 mm.

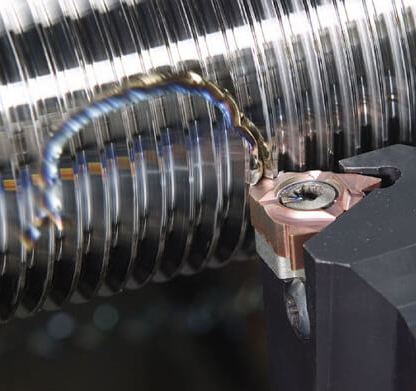

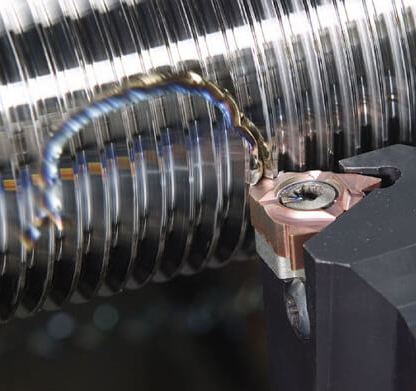

Using cutting tools made from advanced carbide alloys from leading manufacturers allows processing of all types of materials and their alloys, including:

- Ferrous metals (ordinary and high-carbon steels, tool steel, cast iron);

- Stainless steel (medical, food-grade, industrial);

- Non-ferrous metals (copper, brass, bronze, aluminum, duralumin, titanium);

- Composite materials (caprolon, textolite, plastics, carbon fiber, polymers, etc.);

- And more.

Performing turning work is a complex technological process with manual/automatic control at every stage. High-precision calibrated micrometers or gauges are used as measuring instruments.

Whether it is turning copper, aluminum, steel, and stainless steel parts on a lathe or processing titanium parts—quality results depend on the following technological process requirements:

- The workpiece rotates at the proper speed according to the calculated processing mode;

- The maximum possible metal layer is removed per cutting pass;

- The lathe machine is in perfect technical condition with all units functioning properly.

CNC turning is divided into roughing and finishing operations. The cutting speed mode depends on the hardness of the part, chosen cutting tool, spindle speed, and other parameters, all of which are controlled and included in the turner's services.

BK "VIMALSPETSBUD" is a leading manufacturer of parts and mechanisms for various industries. We produce parts of different complexity, shapes, and designs made of steel, cast iron, non-ferrous alloys, and plastics according to customer technical requirements and drawings. Thanks to many years of experience, professionalism of our specialists, and a modern machine park, we guarantee high product quality, adherence to deadlines, and reasonable prices.

Today, for our clients, we offer:

- Serial production of parts on CNC machines (with an individual discount system for increased order volumes);

- Non-serial work and prototype manufacturing;

- Guarantee of compliance with all drawing requirements (accurate dimensions, tolerances, and material compliance);

- Precise planning of all production processes.

We are located in Chernihiv and perform turning work of various complexity. You can order turning services from BK "VIMALSPETSBUD" via online application or by phone. (Go to contacts)