A slide gate valve is an essential auxiliary component used during controlled processes for unloading and loading into various systems under pressure. It is applied in the agricultural, logging, chemical, and food industries.

Slide gate valves (feeders, dispensers) are designed for uniform discharge or dosing of dry products such as grain, flour, wood shavings, sawdust, dry milk from cyclones, bunkers, and containers. Slide gate valves prevent the ingress of atmospheric air into low-pressure systems or the escape of gases from high-pressure systems, thereby maintaining constant pressure within the installation.

Slide gate valves are used for transporting products via mechanical or pneumatic feeding. Essentially, this device functions as a shut-off and control valve, meaning it regulates and blocks the flow of material.

Slide gate valves come in two types — discharge and loading. The first type is used for unloading bunkers and cyclones that are under pressure.

Depending on the hardness of the bulk product and the volume of the mixture supply, the sizes of the slide gate valves, internal chambers, and inlet and outlet openings are calculated.

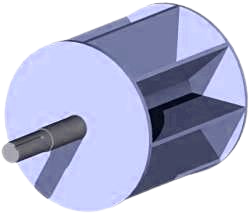

Slide gate valve construction

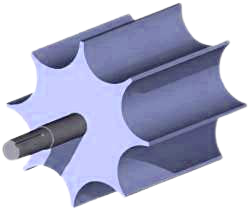

The blade rotor is the main element of the rotary feeder. It ensures minimal clearances, which facilitates material discharge without losses or spillage, and provides a sealing and dosing function. Using this sealing mechanism, it is possible to:

- to shut off the flow of any working medium;

- to combine multiple flows simultaneously;

- to redistribute flows from different main lines;

- to discharge excess gas or liquid (if necessary).

Motor-reducer: the feeder operates on an electromechanical drive that provides the required rotation speed.

The housing ensures the integrity of the equipment and, thanks to flanges, allows for easy and precise integration of the rotary valve into the technological line. The housing has two necks: an inlet (loading) and an outlet (discharge), positioned vertically. The rotary valve housing is available with a square inlet (RV) or a round inlet (RVR).

The operating principle of the rotary valve is as follows:

The rotary mechanism consists of a drum rigidly mounted on a shaft, divided into several compartments that act as "pockets" for product feeding. The rotation of the rotary mechanism is driven by an electromechanical drive (motor-reducer). As it turns around its axis, the drum compartments capture particles of the bulk material inside the hopper and transport them downward, discharging the material under the force of gravity. Acting as a discharge valve, the rotary valve maintains tightness, ensuring minimal air leakage from the hopper.

The capacity of rotary sector valves can vary depending on the rotor’s rotation speed and the volume of the compartments.

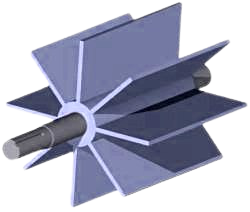

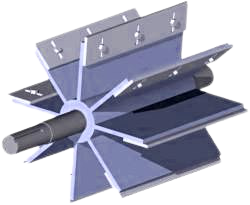

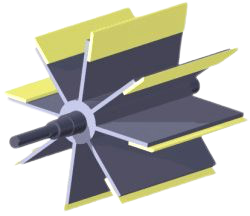

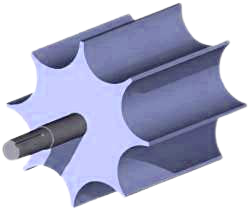

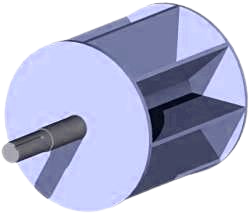

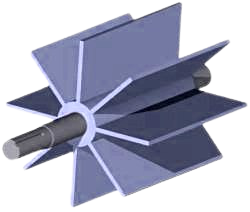

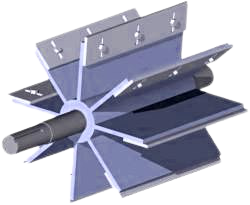

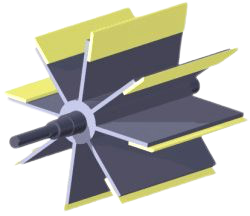

| Types of vane rotors in a rotary valve |

Image |

|

Closed-end rotors

Closed-end rotors reduce air leakage. They prevent wear of the side covers of the rotary valve when working with abrasive materials.

|

|

|

Open-end rotors

Open-end rotors are typically used in blow-through type rotary feeders installed on pneumatic conveyors.

|

|

|

Rotors with adjustable blades

Adjustable blades are used when working with abrasive materials to increase service life.

|

|

|

Sealed rotors (with elastic blades)

Polyurethane or rubber is used as sealing material. Elastic blades are used for bulk materials with large particles, as well as for abrasive powders.

|

|

|

Toothed rotors

The toothed rotor design is suitable for sticky materials. They are also used in the food industry.

|

|

Advantages of the rotary valve from BK "VIMALSPETSBUD":

- Versatility;

- Smooth material feeding;

- Easy access to internal mechanical parts;

- Precise alignment and absence of rotor shaft deformation;

- Airtightness;

- Increased wear resistance due to simple and reliable design;

- Operable within a wide temperature range;

- Suitable for use both indoors and outdoors.

The rotary valve features high maintainability. Routine servicing and repairs can be carried out in standard production environments. Additionally, all bearing units in this device are located outside the housing, which extends their service life and minimizes the risk of exposure to process flows.

Gate valve mechanisms are distinguished by their compactness and ergonomic design. They occupy minimal space, allowing installation in virtually any system. This simplifies and reduces the cost of fitting the valves. Their compact size enables installation in pipes of various diameters (from 50 mm up to over 100 mm). These valves are versatile and can be mounted on pipelines transporting almost any bulk or granular material.

We are located in Chernihiv and manufacture rotary airlocks (gate valves) to order, based on customer requirements, within the shortest possible time and at attractive prices. You can purchase rotary airlocks produced by VIMALSPETSBUD through submitting an online application or by contacting us by phone. (Go to contacts)