VIMALSPETSBUD manufactures silos, bunkers, and containers for cement, grain, flour, sand, as well as feed, construction mixes, various fertilizers, and other bulk materials. Alongside various tanks, reservoirs, and containers, the steel silos and bunkers are custom and large-scale metal structures, requiring special transportation conditions to the site of operation. The demand for modular silos is very high, driven by the growing number of expanding enterprises engaged in production or storage of materials.

Silos, bunkers, and containers from VIMALSPETSBUD can be used for:

- agricultural products;

- coal and construction industries;

- food sector;

- human activities;

- chemical enterprises;

The production of silos, bunkers, and containers requires considerable expertise. Therefore, their manufacture is classified as non-standard. Most often, steel bunkers are custom-made based on individual orders and customer requirements, taking into account that the dimensions must fit the volume of the facility where they will be installed. In such cases, the assistance of experienced specialists is essential to perform accurate calculations of the parameters for the future installation.

Bunker, Receiving Bunker, Storage Bunker from BK "VIMALSPETSBUD" – Bunker Keeper

Bunkers are box-like structures designed for the temporary storage and transfer of various materials such as coal, ore, root crops, crushed stone, and bulk materials. Each bunker features a loading opening at the top and a discharge opening at the bottom, which is sealed with a gate valve. They can be either stationary or mobile.

Discharge openings come in various shapes: rectangular, round, conical, slotted, and others.

By installation type, bunkers are classified as: above-ground, semi-buried, and underground.

The most common bunker shapes are: rectangular, pyramidal, and rectangular-combined.

The combination of multiple bunkers within one structure is called a bunker trestle. Bunker capacities vary widely, often reaching 100 m³ or more.

The shape of the bottom, the slope of the side walls, and the size of the discharge opening must be designed to ensure that the contents flow out without delay.

Attention! An incorrectly selected cross-section and an insufficiently sized hatch can hinder the discharge of material. To ensure proper material flow from the bunker, the angle of inclination of the ribs on the side walls to the horizontal must exceed the natural repose angle of the material at rest by at least 5–10%.

Silos by BK "VIMALSPETSBUD" — Silo Keeper

Silos are designed for storing bulk product reserves. These can include food products such as grain, wheat, rice, corn, and seeds, as well as industrial materials like sand, cement, dry mixes, and others. Silos protect the product from atmospheric precipitation, sunlight, and prevent spoilage of grains and cereals by rodents and birds.

A silo is a vertical cylindrical container. The bottom is typically conical in shape and features an outlet for unloading the contents. The roof can be either flat or conical. Externally, the silo is equipped with supporting elements (steel framework and platform), maintenance equipment (ladders, handrails, etc.), as well as special devices for loading and unloading (valves, pumps, and others).

An undeniable advantage of steel silos is their capacity. Given that a silo is a vertical container by design, it occupies only a few square meters of floor space despite holding a large volume of bulk materials. For example, a steel silo with a volume of 100 cubic meters occupies about 9 square meters of area.

VIMALSPETSBUD designs and manufactures bunkers and silos that are integral parts of technological lines. Our experienced engineers also perform preliminary calculations of volume, capacity, and productivity of the bunkers, as well as engineering assessments of the loads on the bunker walls.

When designing containers such as bunkers or silos, it is essential to consider their geometric dimensions and shapes that comply with a range of specific requirements.

Typical configuration of silo and bunker structures from BK "VIMALSPETSBUD":

- Steel tank of various shapes: cylindrical or rectangular (customized to meet your production needs);

- Supporting structures;

- Service platform (inspection platform with railing);

- Stairs to access the platform (with or without railing);

- Flange for the discharge opening on the tank cone;

- Hatch with cover;

- Inspection windows.

Materials used in the manufacture of bunkers and silos are high-quality steel and stainless steel, coated with anti-corrosion compounds that enable operation in any climatic conditions and guarantee long service life. The exterior metal surfaces are covered with special paints to protect against corrosion and environmental effects. If necessary, the silo or bunker can be additionally insulated externally.

We offer additional equipment options for silos and bunkers from BC "VIMALSPETSBUD":

- Level sensors for monitoring the fill level of the container;

- Process automation systems;

- Rotary airlocks;

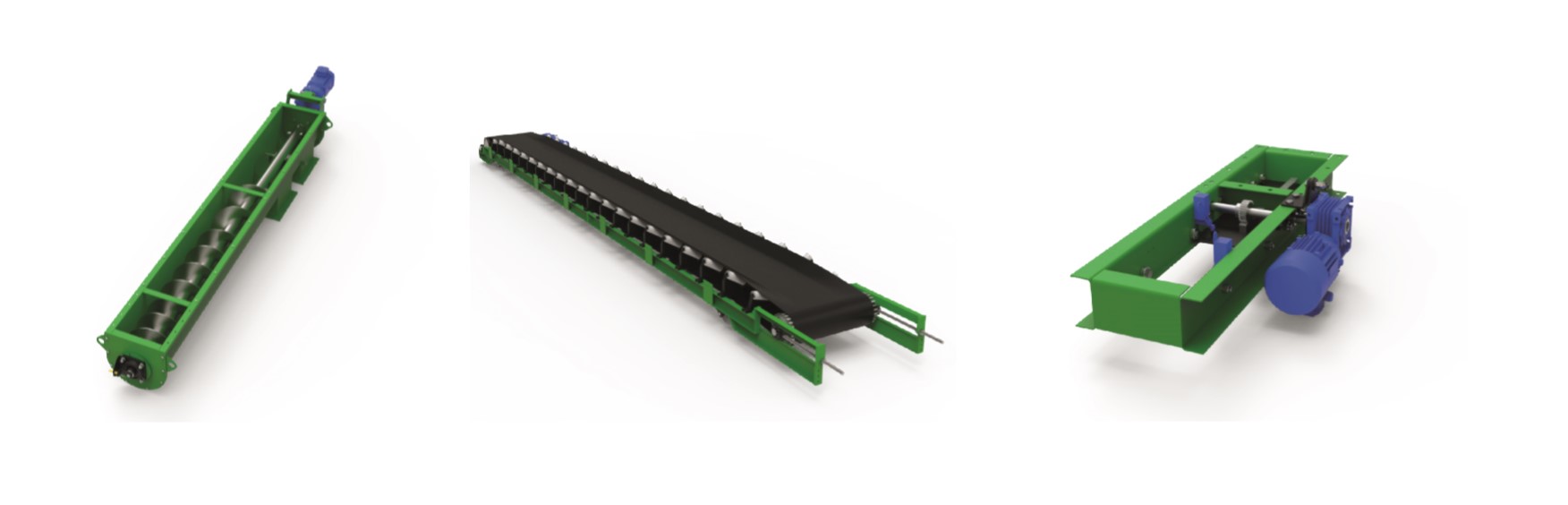

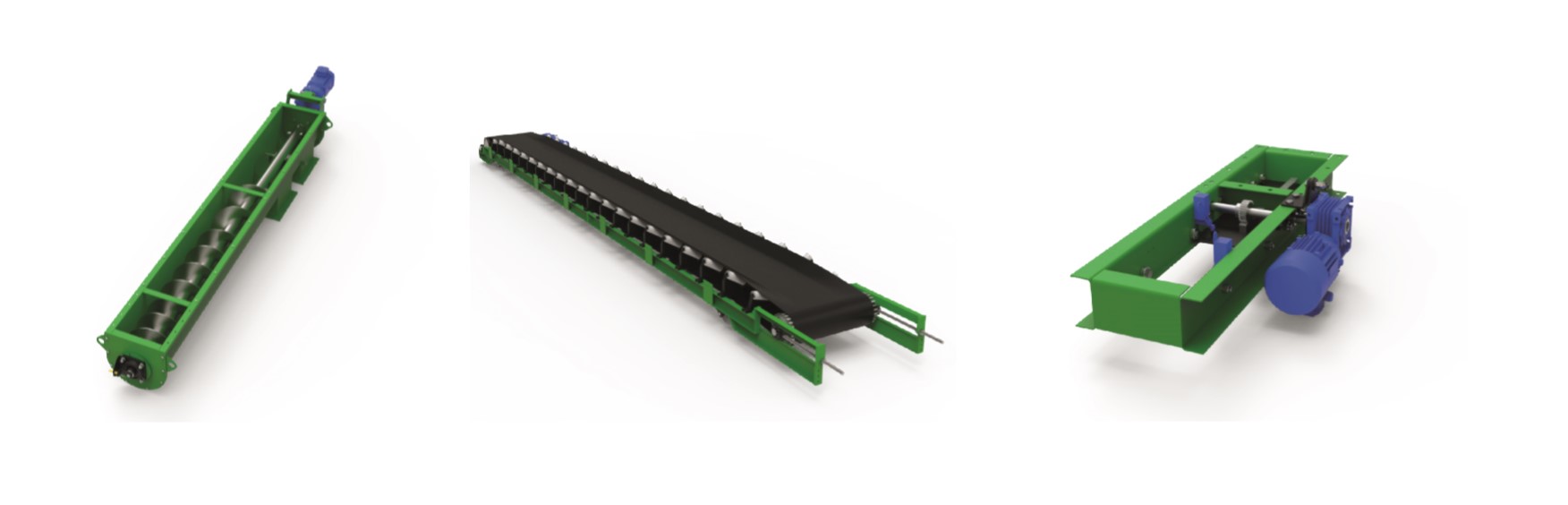

- Belt and screw conveyors;

- Grain chutes, rotary valves, flanges of various configurations.

Silos, bunkers, and containers from BK "VIMALSPETSBUD" offer the following advantages:

- Strength — thanks to the use of high-quality steel combined with reinforcing elements, the structure withstands significant mechanical loads without damage, maintaining its shape under the influence of contents and external environment

- Reliability — welded seams undergo quality control and testing, ensuring their durability and long service life;

- Ease of loading/unloading contents — thanks to their cylindrical or rectangular shape, the bunkers allow for convenient loading and unloading of materials.;

- Compactness of silo storage — occupies a small footprint, enabling the creation of storage facilities for cement, sand, flour, or other materials of any size on a limited land area.

We are located in Chernihiv and manufacture silos, bunkers, and containers to order, based on customer requirements, within the shortest possible time and at attractive prices. You can purchase silos, bunkers, and containers produced by VIMALSPETSBUD Construction Company by submitting an online application or contacting us by phone. (Go to Contacts)