Rotary Water Cleaning Screens CLEAN MASTER from VIMALSPETSBUD LLC is a high-tech, economical, and self-cleaning equipment designed to solve your water purification challenges where high-efficiency removal of foreign particles and debris from the main flow is required.

Rotary Water Cleaning Screens CLEAN MASTER from VIMALSPETSBUD LLC are indispensable for:

- Environmental protection (used as a fine mesh screen for preliminary wastewater treatment at the inlet of treatment facilities, in surface water catchments for municipal and industrial purposes for pre-filtration, and in industrial systems for preliminary water purification);

- Secondary processing (for preliminary water purification in plastic washing systems, filtration of cooling water discharged from processes, and for pre-treatment of wastewater before it is sent to treatment facilities);

- Meat processing and poultry farming (for mechanical preliminary wastewater treatment in slaughterhouses at the inlet to treatment facilities, for pre-cleaning after washing of offal, for pre-treatment of water after poultry processing on feather removal machines, and for pre-treatment of water after washing of process transport equipment);

- Fish farming industry (for preliminary wastewater treatment at facilities preparing and processing fish products, for continuous water filtration at fish farms, and for cleaning circulating water from organic residues);

- Sugar industry (used as stone catchers, for filtering conveyor washing waters, and for cleaning circulating water);

- Food industry (at vegetable and fruit processing enterprises for mechanical preliminary wastewater treatment, continuous filtration of conveyor washing waters, and localized pre-treatment of water after washing vegetables or fruits);

- Brewing industry (for preliminary treatment of brewery wastewater and filtration of water after cleaning fermentation tanks).

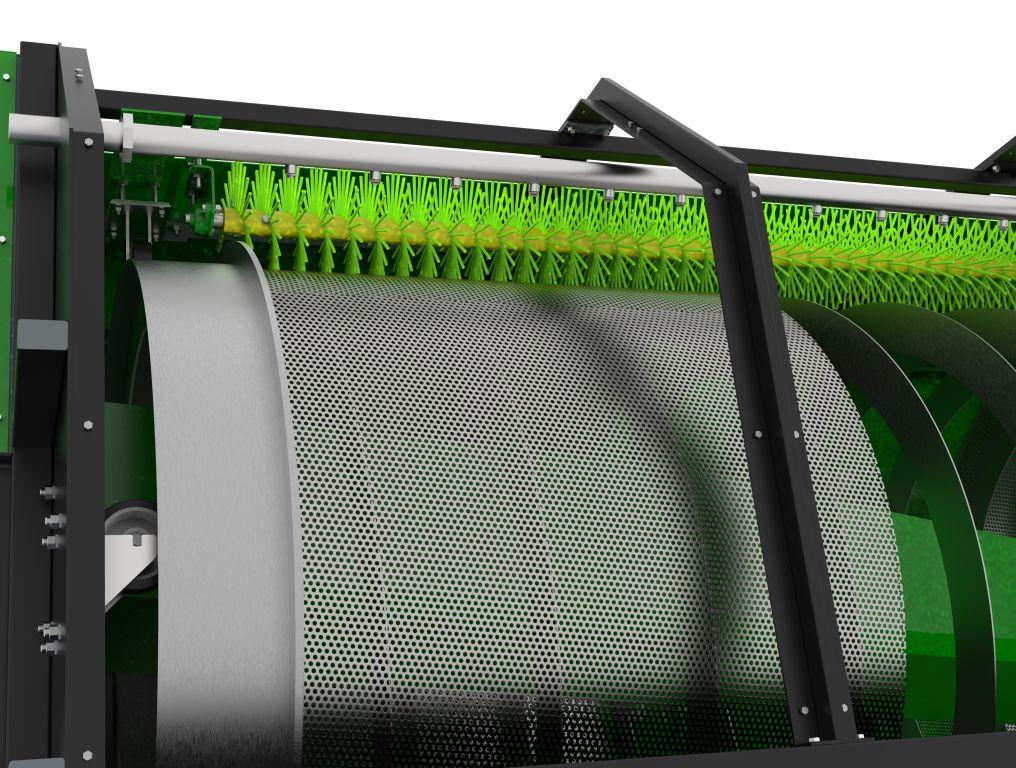

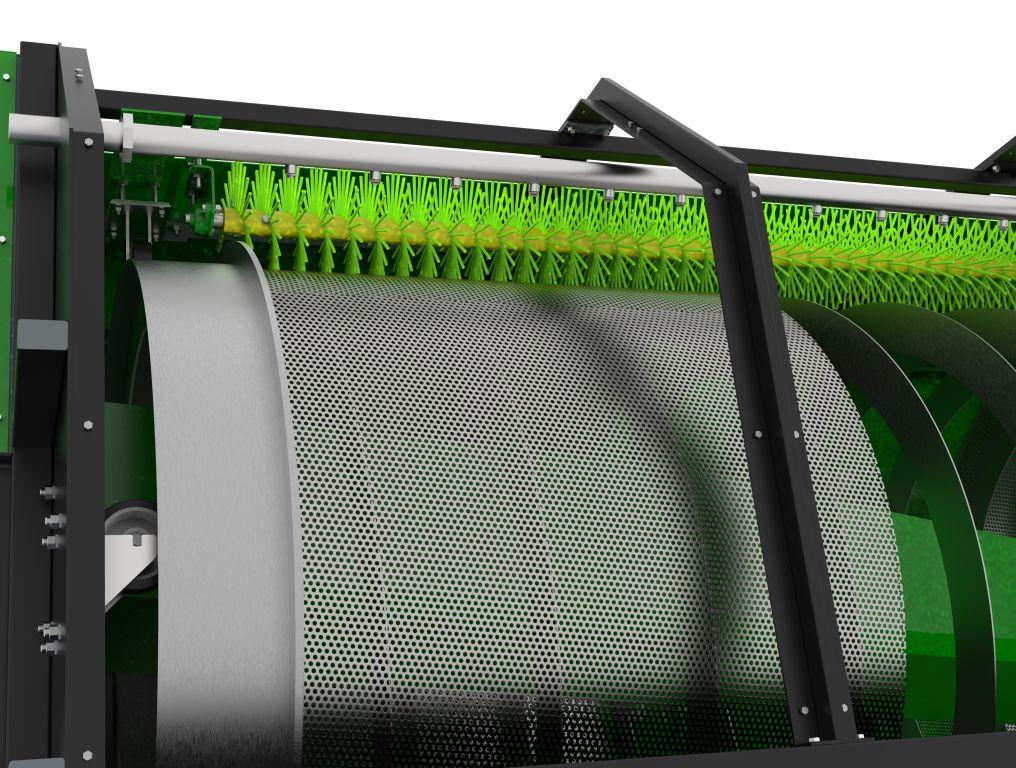

Operating principle and main components of rotary water cleaning screens by BK “VIMALSPETSBUD”:

- Tank, drum, cleaning pipe;

- Side and rear covers;

- Top cover;

- Motor-reducer;

- Hopper; brush; shaft.

Contaminated water is fed into the rotary screen through a hopper (with dampers), evenly distributed over a large area of the drum (to effectively utilize the entire perforated surface), and then flows down the trough into the drainage pipe. Solid substances (suspended particles, long fibers, sand, etc.) with particle sizes larger than the filter openings remain inside the drum and are conveyed by a spiral to the discharge outlet.

The rotary screen is enclosed on all sides with removable covers and equipped with an exhaust ventilation opening to improve the working environment in the facility where it is installed. For example, we recommend installing this equipment instead of or after the rake section of treatment plants, which significantly reduces the size of the facility and energy consumption

|

|

|

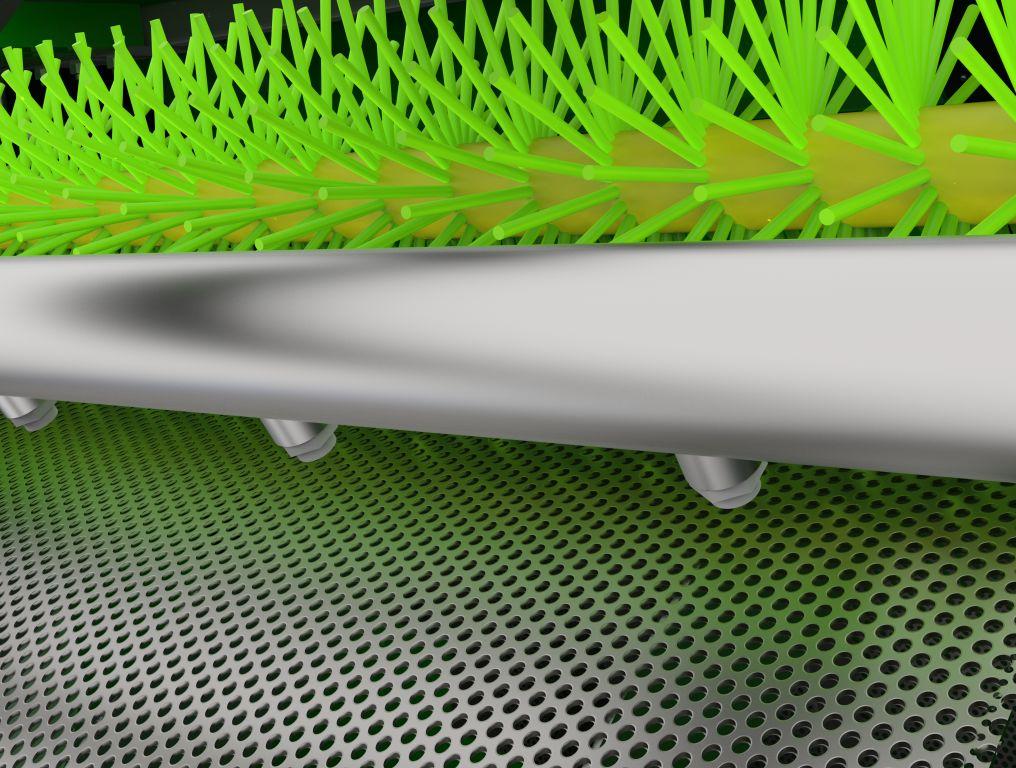

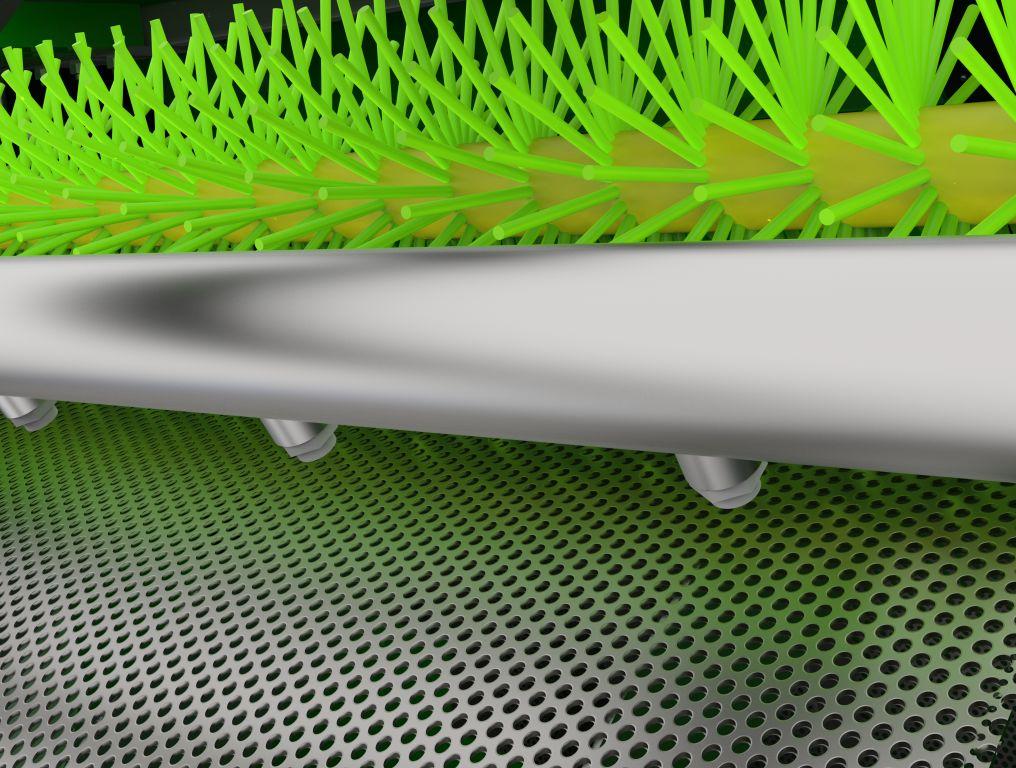

| Brush and cleaning tube |

|

Rotary screen |

Moreover, unlike outdated solutions, our filter removes all particles sized 2 mm and above at the initial stage along with the wastewater. CLEAN MASTER also helps reduce the load on sand traps, aeration tanks, and settling tanks, which in turn significantly lowers the biological oxygen demand at wastewater treatment plants during the purification process

As a result, by integrating our rotary screen into your treatment plant system, you will reduce your biological treatment station’s electricity consumption by 20-25%

CLEAN MASTER is our proprietary development that successfully performs its functions at processing enterprises across Ukraine.

Self-cleaning of CLEAN MASTER rotary water screening sieves. To reduce filter contamination during operation, a pressure washing system is used. It provides contactless cleaning of the inner surface of the drum. Weekly maintenance consists only of visual inspection of the drum and the washing system nozzles. The nozzles are easily removable for cleaning or replacement when necessary. For additional cleaning of the filtering drum, the rotary screen can be equipped with a rotating brush, ensuring uncompromising filter cleaning even in the most contaminated flows.

Maintenance of CLEAN MASTER rotary water screening sieves. The simple and well-thought-out design of our equipment requires only periodic inspections during operation. Thanks to the tight screens that open easily, this process will take you minimal time.

We guarantee high product quality, ease of maintenance, and timely delivery. The pinnacle of our research and experience is the flagship model of the CLEAN MASTER rotary filter, which combines the best technical solutions with factory production quality, controlled at every stage.

| High efficiency |

Excellent filtration level thanks to the perforated drum and pressure-free separation principle |

| Thanks to innovative technical solutions, there is no need for preliminary filtration |

| There are no gaps or openings through which debris can pass — the entire flow passes through the filtering screens |

| High productivity with an excellent filtration efficiency rate |

| Simple and straightforward design |

Minimum moving parts |

| Easy maintenance thanks to an efficient self-cleaning system |

| Extremely simple process for complete visual inspection and control |

| Lightweight screens that open at all necessary inspection points |

| Low consumption |

The drum is designed for an average operational lifespan of 20 years |

| A small number of moving parts makes maintenance very simple, even without special tools or equipment |

| Minimum electricity consumption |

| Significantly reduced clean water consumption for the filtration system thanks to spray nozzles |

We take full responsibility for everything—from sizing to on-site installation—and thanks to our involvement in the planning stage, we will design, quickly and efficiently manufacture the CLEAN MASTER model tailored precisely to your needs, providing a full guarantee of process performance

We are located in Chernihiv and manufacture custom rotary water cleaning screens with fast turnaround times and competitive prices. You can purchase rotary water cleaning screens produced by VIMALSPETSBUD through our online application form or by contacting us via phone. (Go to Contacts)